Description

The M2 FLEXFLO Peristaltic Metering Pump is a positive displacement chemical metering pump that delivers smooth, continuous chemical feed. It is especially effective when injecting chemicals that off-gas like Peracetic Acid and Sodium Hypochlorite. The peristaltic technology is a near-continuous flow that delivers consistent precise flow without the need for check valves.

Product Overview / Features of the M2 Peristaltic Pump

- The M2 pump can deliver up to 21.23 GPH (80.4 LPH) at 100% motor speed.

- Up to 125 psi. (See specific tube ratings and tube life data before choosing a tube)

- Brushed DC Motor capable of 200:1 turndown.

- NSF 61 Listed.

- 9-button LCD Display.

- Manual Speed Control.

- Remote Start/Stop.

- 4-20mA input and 4-20mA output. Fully scalable at the pump.

- Pulse and Frequency input speed control.

- One Alarm Output. (TFD leak detection and FVS flow verification)

- Motor Status output.(contact closure, open collector)

- Integral TFD leak detection.

- FVS (Flow Verification System) input. (Flow sensor is ordered separate)

- Manual Prime.

- Wetted parts are PVDF connectors and, Flex-A-Prene, Flex-A-Chem, or Flex-A-Thane tubing.

- Removable terminal blocks and junction box for communication wiring.

- 5 Year Limited Warranty.

Applications

The M2 pump is designed to provide smooth chemical feed for a variety of chemicals and processes. It can reliably pump chemicals that off-gas such as sodium hypochlorite, peroxide, ammonia, and PAA (peracetic acid), as well as a variety of other chemicals.

The M2 is effective with suction lifts, polymers, slurries, and solutions with minor debris that would normally cause issues with diaphragm pumps.

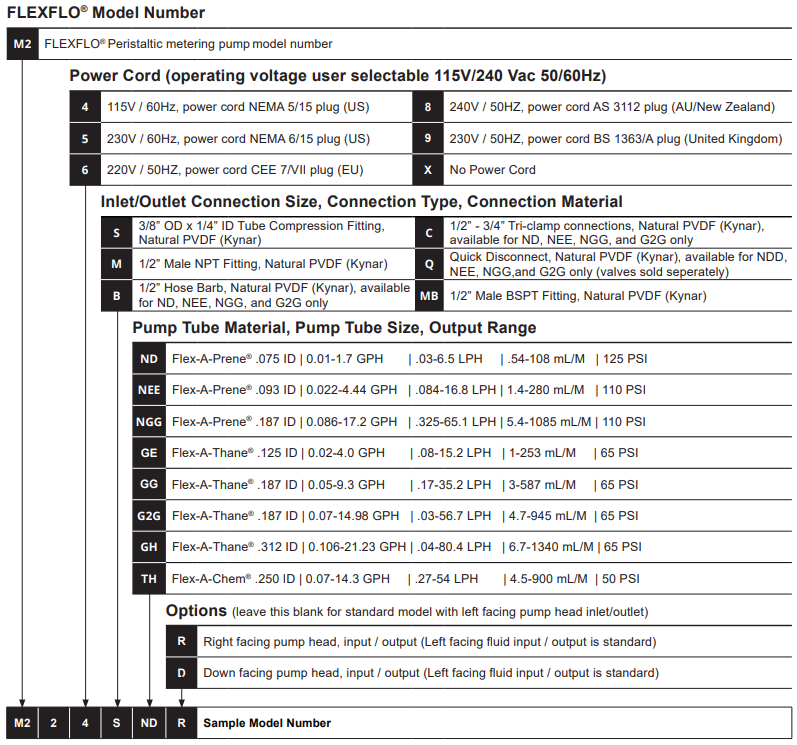

Product Matrix

Use this matrix to reference your product number.

FAQs

Frequently Asked Questions

M2 Introduction

- What does CIP and SIP mean?

"CIP stands for Clean-in-Place. It is an automated method of cleaning process equipment without the need to disassemble it. CIP uses chemicals, heat, and water to thoroughly clean machinery, including elements such as pipes, filters, and fittings. SIP stands for Sterilization-in-Place or Steam-in-Place. It is an extension of the CIP process by an additional sterilization step. SIP uses steam at high temperatures (> 121 °C) to kill any microorganisms that may be present in the equipment."

Define “Meets FDA criteria for food”. What does that mean?When a product is said to "meet FDA criteria for food," it means that the product has been developed, manufactured, and labeled in accordance with the regulations and standards set forth by the United States Food and Drug Administration (FDA) for products intended for human consumption.