Performance

Maximum Fluid Temperature: 130 °F (54 °C)

Maximum Viscosity: 5,000 Centipoise

Maximum Suction Lift: 30 ft at sea level (14.7 atm psi)

Electrical and Controls

Electrical Power Requirement:

- 115VAC/60Hz, 1ph (.51 amp max)

- 230VAC/60Hz, 1ph (.56 amp max)

- 220VAC/50Hz, 1ph (.66 amp max)

- 240VAC/50Hz, 1ph (.58 amp max)

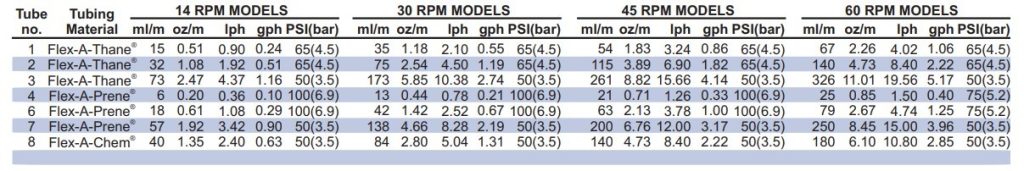

Motor: DC, Gearmotor, 14 rpm, 30 rpm, 45 rpm, or 60 rpm.

Power cord options available (6 feet in length):

- 115VAC 50/60HZ, NEMA 5/15 plug (U.S.) – (choose when specifying pump model)

- 220VAC 50/60HZ, CEE 7/V11 plug (EU) – (choose when specifying pump model)

Signal Connections: Color-coded wires, liquid-tight junction box.

Inputs:

- FVS (Flow Verification System) (Flow sensor ordered separately)

Outputs:

- Alarm Output – Open collector output. Activated by TFD (leak detection) and FVS (flow verification – flow sensor ordered separately)

- Motor On Status – Open collector output.

Materials of Construction

Pump Head: Valox® (PBT)

Pump Head Cover: Acrylic, with permanently sealed motor shaft support bronze sleeve bearing.

Cover Screws: Stainless steel, polypropylene cap.

Roller assembly: Rotor – Valox, Rollers – Nylon, Roller bearings – Bronze.

Motor Shaft: Chrome-Plated Steel

TFD Sensor: Hastelloy C-276 pin contacts

Power Cord: 3 Conductor, SJTW-A water-resistant

Enclosure: NEMA 3R (IP23) Valox

Tube Assembly Options

Flex-A-Prene® tubing – An excellent material for most water treatment applications. Chemically resistant to 25% Sodium Hypochlorite, 30% Sulfuric Acid, 30% Fluosilicic Acid, Ferric Chloride, Alum, and many others.

Flex-A-Chem® tubing – This material consists of an outer Norprene jacket with an inner liner that is virtually unaffected by acids, bases, salts, ketones, and alcohols.

Flex-A-Thane® tubing – This polyurethane material can be used with a variety of chemicals, including Oil and Water based Polymers, fuels and lubricants, and many others.

Dimensions and Weights

Maximum Overall Dimensions: 9.5” W x 6.0” H x 9.125” D (24.1 W x 15.2 H x 23.2 D cm)

Product Weight: 8.5 Lb. (3.8 Kg)

Approximate Shipping Weight: 12 lb. (5.4kg)

Agency Listings

cETLus

RoHS Compliant

FAQs

Frequently Asked Questions

A-100NF Specifications

- Does the A-100NF have any output alarms?

The A-100NF pump can be wired for open collector output alarm (TFD or FVS alarm condition.)

Is the A-100NF rated NEMA 4X?No. The A-100NF pump enclosure is rate NEMA 3R (IP23).

What tube materials are available for the A-100NF?Tube materials available for the A-100NF are Flex-A-Prene® , Flex-A-Chem®, Flex-A-Thane®.

What is the minimum percentage speed the A-100NF can run?The A-100NF pump can run to a minimum percentage of 10% (10:1 turndown).

Will the leak detection TFD work with polymers?The TFD leak detection operates on the conduction of the solution being pumped. Most polymers do not conduct electricity well and the TFD will not work or activate with these solutions. When pumping polymers, or other solutions that do not conduct electricity well, we recommend using the A-100NFP or A-100NVP Polymer Pumps which use the TFD+ detection.

Why does the adjustment range begin at 5%?The adjustment range begins at 5% due to the minimum amount of current required to start the motor from a locked rotor current condition and the load the tube applied on the motor. The locked rotor current is the amount of current that a motor draws when it is started, and the rotor is still.

What is the adjustment range in motor %?The adjustment range allows the user to fine-tune the speed of the pump. The adjustment range in motor % in a Blue-White A-100N pump varies depending on the tube and motor rpm of the pump (see attached chart). The adjustment range is controlled by a dial knob on the front of the pump. By turning the knob, the user can increase or decrease the speed of the pump. The dial knob is marked with percentages, so the user can easily see how much the speed has been adjusted.