What’s in the Box

The A2 Pump is shipped with the following contents:

- A2 Peristaltic Metering Pump

- Two tube assemblies (one installed, one spare)

- Tube installation tool

- Power Cord – 6 feet

- USB Drive (Operating manual)

- Mounting hardware kit (includes standard mounting brackets and hardware)

- Suction strainer, PVDF (with “S”, “M”, and “B” tube connectors only)

- Discharge injector, PVDF/Aflas with 1/2 psi check (with “S”, “M”, and “B” tube connectors only)

- Suction tube – clear PVC – 10′ length (3/8″ OD, 1/4″ ID) (with “S” tube connectors only)

- Discharge tube – opaque polyethylene – 10′ (3/8″ OD, 1/4″ ID) (with “S” tube connectors only)

Preparation

The A2 Pump is designed to withstand outdoor conditions, although it is recommended to locate the pump in a protected enclosure for maximum pump life. A cool, dry location where the unit can be easily monitored is recommended. Special ventilation is not required.

The pump can be mounted on a level flat surface. We recommend using the provided mounting brackets for secure installation. Blue-White also offers a sturdy polyethylene (PE) Wall Shelf to mount the pump.

Piping and Physical Installation

The A2 Pump must be level to ensure pumping accuracy.

If mounting the pump using the mounting bracket, follow these instructions:

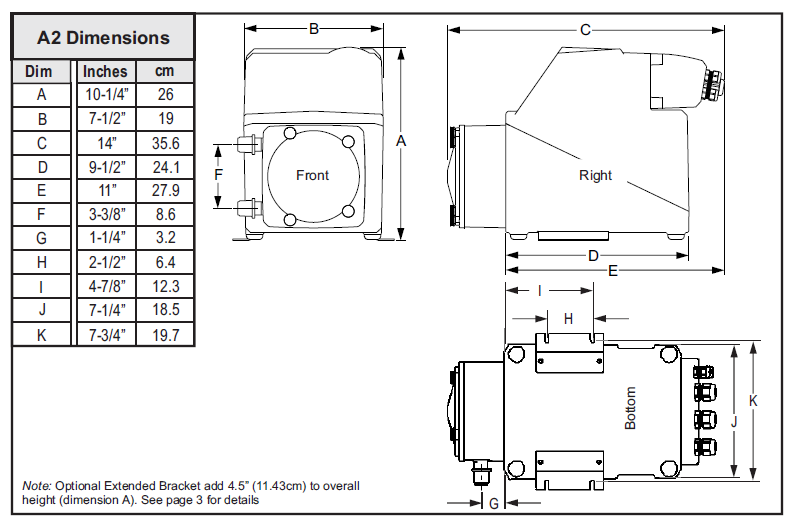

- Use the diagram and drawing on the manual (or below) to mount the pump and bracket to a secure location. We recommend mounting the pump at a height where the display and indicator lights are easily visible, and where it can be easily serviced.

- Ensure the bracket is mounted to the pump first using the provided hardware. (Standard and extended brackets attach to the pump using the same hardware, and hole dimensions are the same. Extended brackets part number 72000-380. Stainless Steel extended brackets allow the pump to be securely mounted to almost any surface: floor, shelf, or skid. Brackets lift pump up 4-1/2 inches (11.43 cm), for easy pump access in hard-to-reach areas.)

- Ensure the location provides enough space for inlet and outlet connections to the pump, and ensure enough space for rear wiring.

- Place the pump and secure it to the base surface using the appropriate hardware for the base surface.

If mounting the pump to a shelf, be certain the shelf will be able to support the weight of the pump.

Connecting Suction and Discharge Tubing/Piping

A2 Pump tube elements have six (6) options for connections.

“S” 1/4’” x 3/8” tubing connections. When A2 pump is ordered with “S” tubing connections, it will come with Injection Check Valve, Suction Strainer, 10 feet of 1/4” x 3/8” clear PVC suction tubing, and 10 feet of 1/4” x 3/8” polyethylene discharge tubing.

“M” 1/2” MNPT connection. When A2 pump is ordered with “M” tubing connections, it will come with Injection Check Valve, and Suction Strainer. Tubing or piping not included.

“B” 1/2” Hose Barb connection. When A2 pump is ordered with “B” tubing connections, it will come with Injection Check Valve, and Suction Strainer. Tubing/hose or piping not included.

“C” Tri-Clamp connection. When A2 pump is ordered with “C” tubing connections, it will not come with Injection Check Valve, Suction Strainer, or tubing.

“Q” Quick Disconnect (Quick disconnect fittings provided separately). When A2 pump is ordered with “Q” tubing connections, it will not come with Injection Check Valve, Suction Strainer, or any tubing. Quick Disconnect fittings must be ordered separately (see accessory options.)

“MB” 1/2” Male BSPT connection. When A2 pump is ordered with “MB” tubing connections, it will not come with Injection Check Valve, Suction Strainer, or any tubing.

Connecting Suction and Discharge Tubing for “S” connection

Clear PVC suction tubing is rated at 50 psi. Opaque polyethylene discharge tubing is rated at 120 psi.

Before connecting the tubing or piping to the pump, be sure the pump is powered OFF. Wear protective clothing and eye protection when connecting tubing to chemicals or chemical lines.

Connect the suction tubing to the pump, and place and secure the other end of suction tubing in the chemical tank/source. Using the provided foot valve/strainer and weight is recommended.

Connect the discharge tubing to the pump and then connect the other end to the discharge point. If using the provided injection valve, be sure to mount it in an upward position to prevent air bubbles from collecting.

Note: We highly recommend installing a check valve on the discharge side of the pump. The check valve can be in the form of an injection check valve, in-line check valve, quick disconnect check valve or similar. When there is a tube leak, the check valve will prevent chemicals in the discharge line from continually feeding back into the pump head.

Wiring

Power Wiring

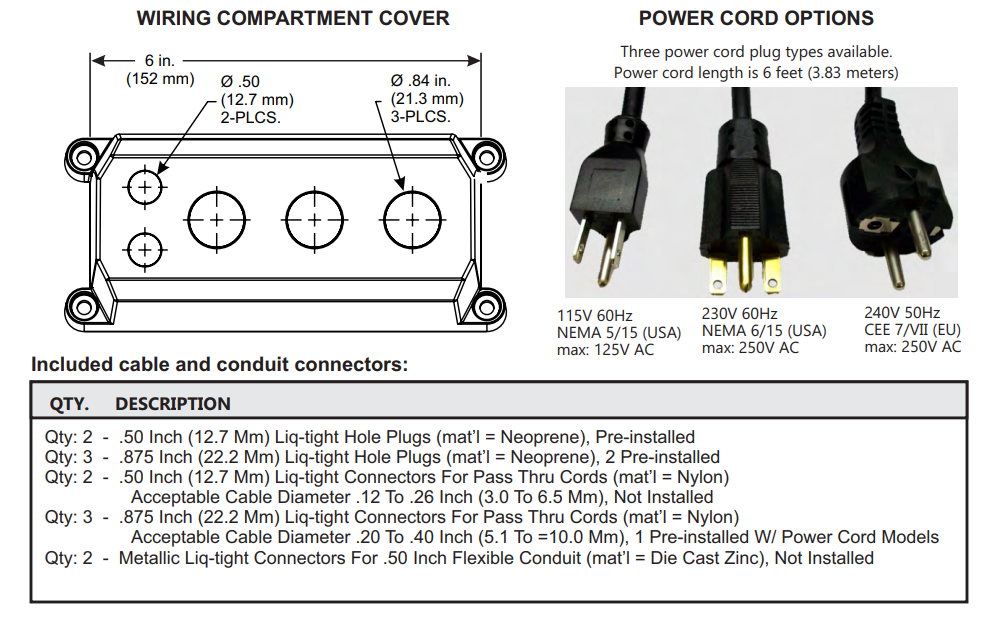

The A2 is powered by 100 to 240VAC, 50/60Hz power. Use the provided 6’ power cord, and attach the cord at the back of the pump.

Caution: Consult a licensed electrician when in doubt about your electrical installation.

Control Wiring

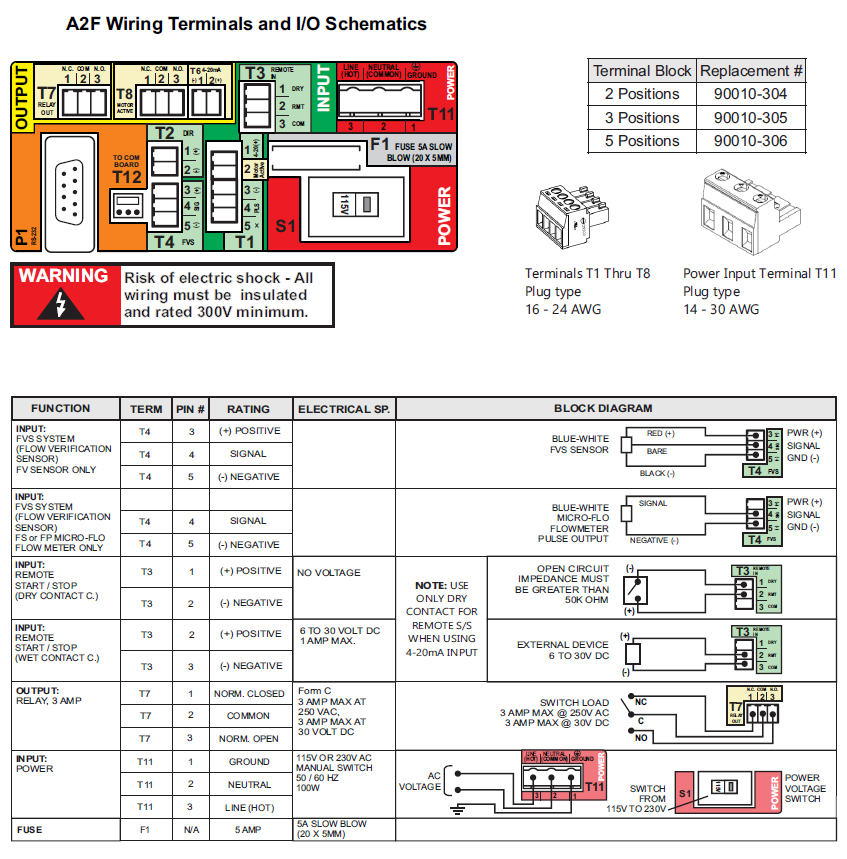

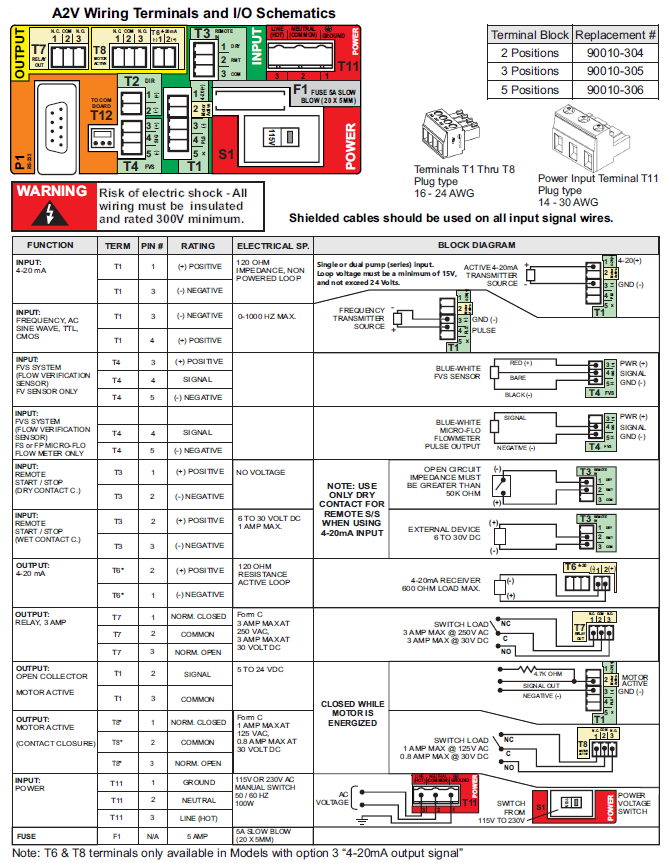

The A2 pump has a labeled terminal box at the rear of the pump. All wiring connections are made via removable terminal blocks.

Signal connection includes:

Input Signals

- Remote Start/Stop Input (Dry or Wet Contact Closure)

- FVS (Flow Verification System) Input

- 4-20mA Input (pump speed control)

- Pulse Input (Frequency, AC Sine Wave, TTL, CMOS)

Output Signals

- 4-20 mA output (Pump speed – scalable) (option)

- (1) Output Alarm

- Motor output (open collector)

- Motor output (contact closure)(optional)

See the below rear panel images and Wiring Chart for information and specifications in connecting to your electrical and control system.

Note: Shielded cables must be used on all signal wiring.

Refer to the instructions in the manual for detailed information.