Your journey to success starts here

We offer a satisfying career in manufacturing at virtually all levels of experience and education. Through training and career development, our team members are inspired and encouraged to achieve their goals while helping to create innovative products.

We are always looking for passionate people who will embrace our core values and vision. We believe in helping our employees achieve their goals both personally and professionally for optimal growth.

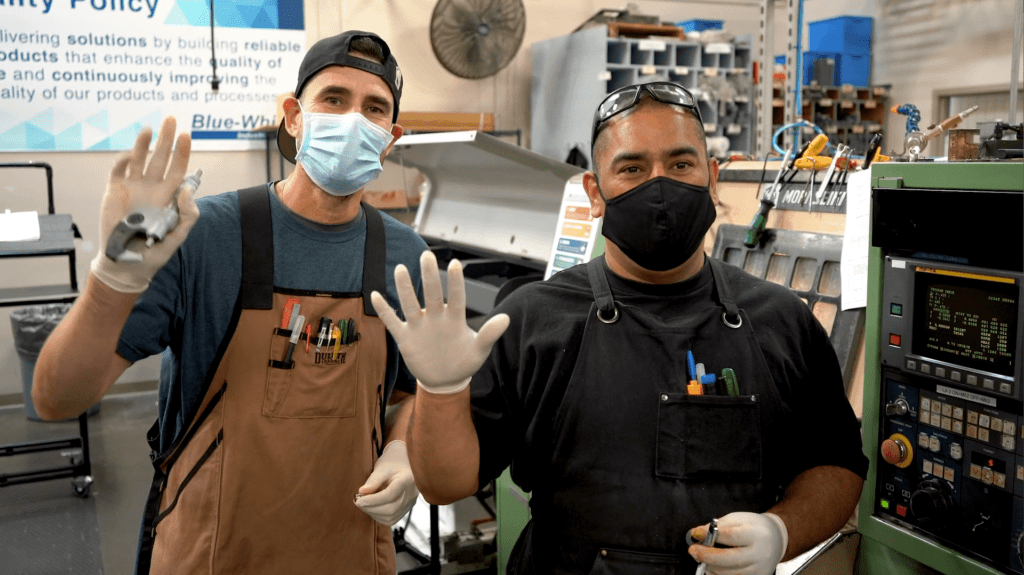

Join a team that is hard-working, passionate, and fun.

At Blue-White, we host a lot of fun company activities that we believe are important for building strong relationships with our team. Come have fun with us!

Join a team that is hard-working, passionate, and fun.

At Blue-White, we host a lot of fun company activities that we believe are important for building strong relationships with our team. Come have fun with us!

Join a team that is hard-working, passionate, and fun.

At Blue-White, we host a lot of fun company activities that we believe are important for building strong relationships with our team. Come have fun with us!

Join a team that is hard-working, passionate, and fun.

At Blue-White, we host a lot of fun company activities that we believe are important for building strong relationships with our team. Come have fun with us!

Join a team that is hard-working, passionate, and fun.

At Blue-White, we host a lot of fun company activities that we believe are important for building strong relationships with our team. Come have fun with us!

Join a team that is hard-working, passionate, and fun.

At Blue-White, we host a lot of fun company activities that we believe are important for building strong relationships with our team. Come have fun with us!

Join a team that is hard-working, passionate, and fun.

At Blue-White, we host a lot of fun company activities that we believe are important for building strong relationships with our team. Come have fun with us!

Join a team that is hard-working, passionate, and fun.

At Blue-White, we host a lot of fun company activities that we believe are important for building strong relationships with our team. Come have fun with us!

Join a team that is hard-working, passionate, and fun.

At Blue-White, we host a lot of fun company activities that we believe are important for building strong relationships with our team. Come have fun with us!

Join a team that is hard-working, passionate, and fun.

At Blue-White, we host a lot of fun company activities that we believe are important for building strong relationships with our team. Come have fun with us!

Previous slide

Next slide

Career Opportunities

Please check back later for new career opportunities!

We Offer Competitive Benefits

We provide full-time employee benefits that will set you up for retirement. Become a part of Blue-White® and work alongside a highly skilled and passionate team that will help you grow and succeed.

- Employee Benefits

- Health care insurance (medical, dental, and vision)

- Life insurance

- 401(k) and Roth 401(k) (matching $0.50 for every $1.00 contributed, up to 6%)

- Paid time off (vacation days, sick days, and paid company holidays)

- 529 college plan

- On-site fitness center

- Commitment to wellness (fitness challenges and reimbursement for fitness event participation)

- Company picnics

- Provided lunch after each quarterly State of the Company address

Our Culture

At Blue-White Industries, Ltd., our motto is “We aren’t satisfied until you are!” – and we live by it every day. With a family-oriented work environment and over 60 years of excellence in manufacturing, we are loyal in supporting our team members to achieve their personal and professional best.

Our Vision

“To continuously improve our people, our processes, and our products to meet the needs of our customer.” It’s why we show up to work each and everyday. It’s what drives us.