What’s in the Box

The A-100NVP Pump is shipped with the following contents:

- A-100NVP Peristaltic Metering Pump

- Two tube assemblies (1 installed, 1 spare)

- Discharge injection fitting with check valve

- Suction tube – clear PVC – 5′ length (3/8″ OD, 1/4″ ID)

- Suction strainer

- Suction ceramic weight

- Discharge tube – opaque polyethylene – 5′ length (3/8″ OD, 1/4″ ID)

- Mounting hardware kit

- Shroud (weatherproof cover)

- Power Cord (if ordered)

Preparation

The A-100NVP Pump is designed to withstand outdoor conditions, although it is recommended to locate the pump in a protected enclosure for maximum pump life. A cool, dry location where the unit can be easily monitored is recommended.

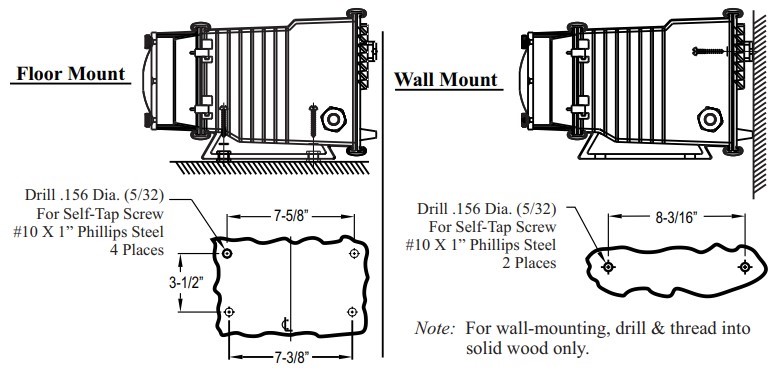

The pump can be mounted on a level, flat surface, or the pump can be wall-mounted. Blue-White also offers a sturdy polyethylene (PE) Wall Shelf to mount the pump.

Piping and Physical Installation

The A-100NVP Pump must be level to ensure pumping accuracy.

If mounting the pump to the wall using the provided wall bracket, follow these instructions:

- Use the diagram and drawing on the manual (or below) to mount the bracket to a secure wall location. We recommend mounting the pump at a height where the display and indicator lights are easily visible, and where it can be easily serviced.

- Mount the pump close to the injection point.

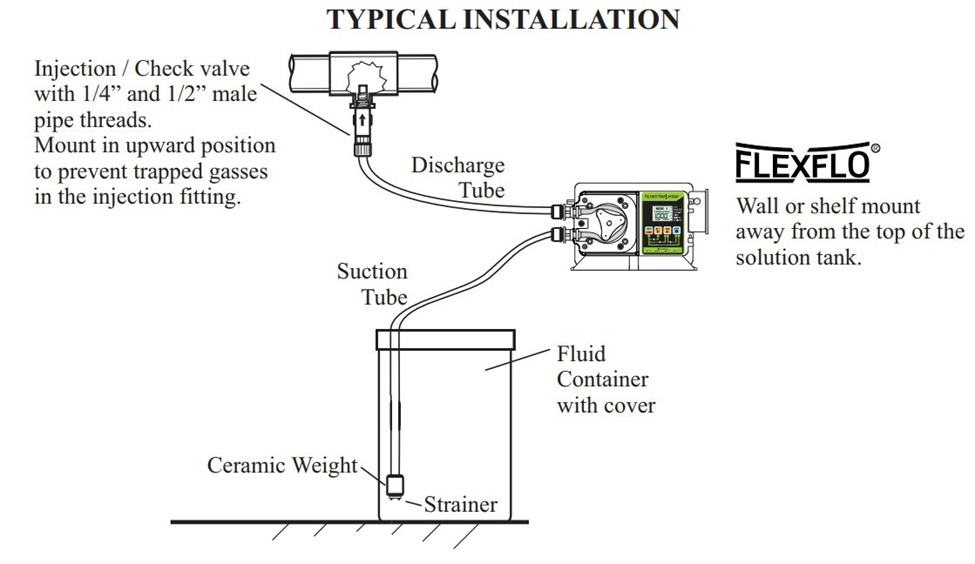

- Mount the pump to the side or lower than the chemical tank.

- Mounting the pump lower than the chemical container will gravity-feed the chemical into the pump. This “flooded suction” installation will reduce output error due to increased suction lift. You must install a shut-off valve, pinch clamp, or other means to halt the gravity feed to the pump during servicing.

Connecting Suction and Discharge Tubing/Piping

A-100NVP Pump tube elements have 1/4’” x 3/8” tubing connections (designated by “T” in the pump or tubing part number.)

The pump will come with suction and discharge tubing, suction strainer, and discharge injection valve.

Before connecting the tubing to the pump, be sure the pump is OFF. Wear protective clothing and eye protection when connecting tubing to chemicals or chemical lines.

Connect the suction tubing to the pump, and place and secure the other end of suction tubing in the chemical tank/source. Using the provided foot valve/strainer and weight is recommended.

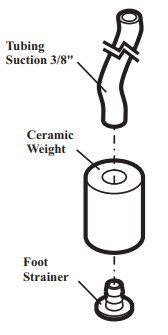

Strainer. – Trim the inlet end of the suction tubing so that the strainer will rest approximately two inches from the bottom of the solution tank. This will prevent sediment from clogging the strainer. Slip the ceramic weight over the end of the suction tube. Press the strainer into the end of the tube. Secure the ceramic weight to the strainer. Drop the strainer into the solution tank.

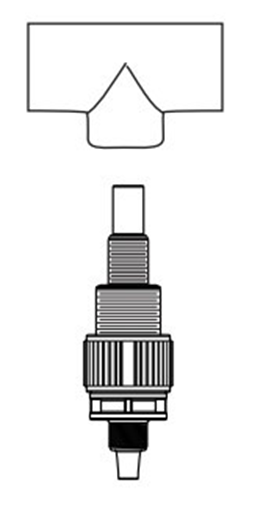

Connect the discharge tubing to the pump and then connect the other end to the discharge point. If using the provided injection valve, be sure to mount it in an upward position to prevent air bubbles from collecting.

Note: We highly recommend installing a check valve on the discharge side of the pump. The check valve can be in the form of an injection check valve, in-line check valve, quick disconnect check valve, or similar. When there is a tube leak, the check valve will prevent chemicals from the discharge line from continually feeding into the pump head.

Wiring

Power Wiring

The A-100NVP can be powered by the following power sources:

- 115VAC/60Hz, 1ph (.51 amp max)

- 230VAC/60Hz, 1ph (.56 amp max)

- 220VAC/50Hz, 1ph (.66 amp max)

- 240VAC/50Hz, 1ph (.58 amp max)

Use the provided 6’ power cord, or an appropriately protected IEC C13 cord rated at 250 volts.

- Be sure to connect the pump to the proper supply voltage. Using the incorrect voltage will damage the pump and may result in injury. The voltage requirement is printed on the pump serial label.

- The pump is supplied with a ground wire conductor and a grounding-type attachment plug (power cord). To reduce the risk of electric shock, be sure that the power cord is connected only to a properly grounded, grounding-type receptacle.

- Note: When in doubt regarding your electrical installation, contact a licensed electrician.

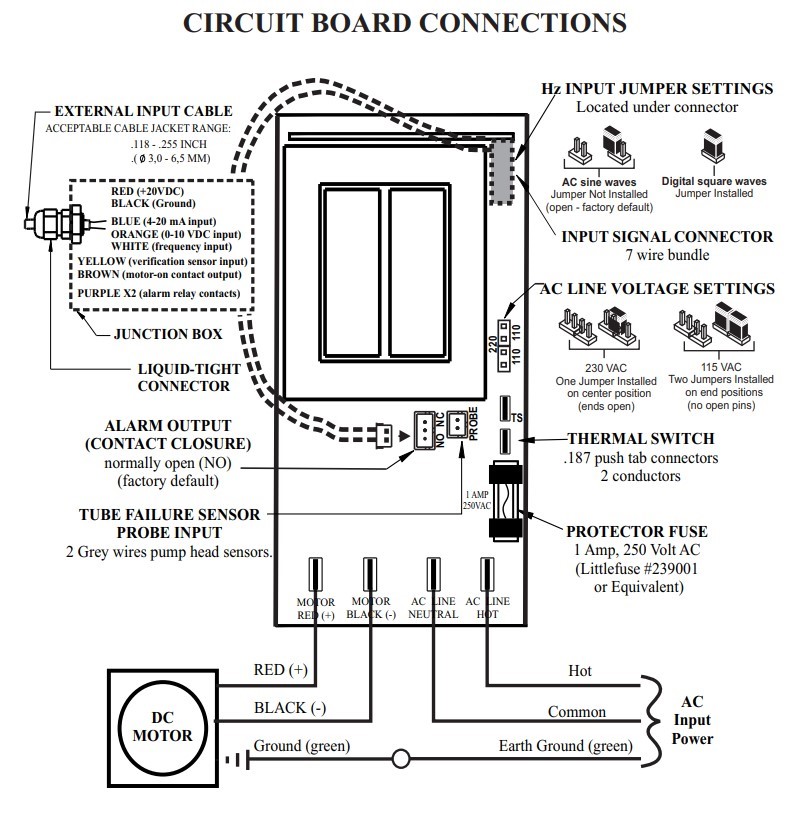

Control Wiring

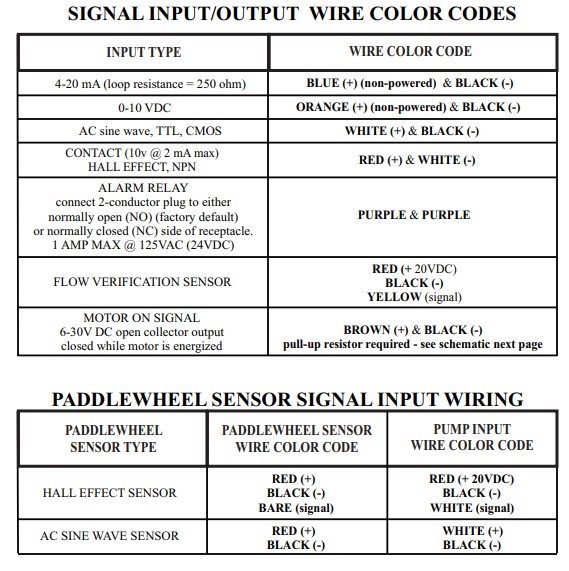

The pump will accept any one of three different types of external input signals;

4-20 mA , 0-10 VDC, or pulse frequency (500 Hz maximum).

The 4-20mA and 0-10 VDC loops must be powered. (A 20 VDC source can be provided by the Red wire in the pump.)

Two types of frequency inputs, AC sine waves (magnetic coils type outputs) and Digital Square waves (Hall Effect signals, contact closures), are acceptable. A jumper plug located on the circuit board is factory pre-set for AC sine wave signals, the jumper must be re-positioned when digital square wave signals are being used.

All wiring connections are to be made inside of the junction box located on the side of the pump. A liquid-tight connector is supplied and should be used for the external signal cable. The signal input wires are color coded to the type of signal being used.

See the below Wiring Chart for information and specifications in connecting to your electrical and control system.

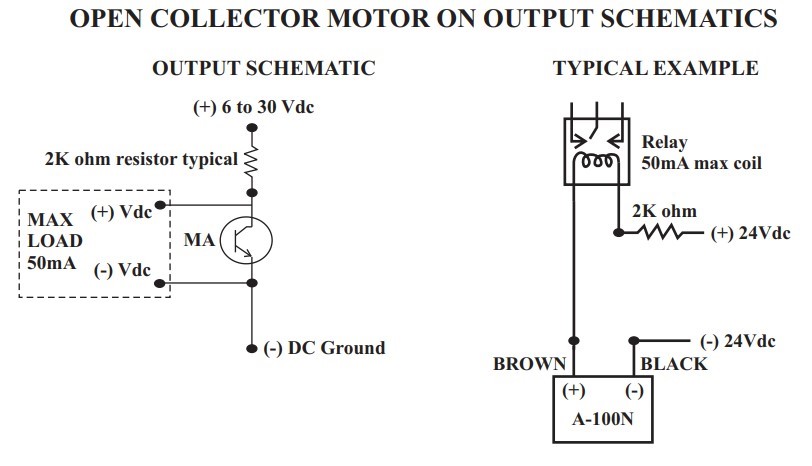

When wiring Open Collector Motor On Output, refer to the below schematics:

Refer to the instructions in the manual for detailed information.