What’s in the Box

The MS6 Chemical Feed Flowmeter is shipped with the following contents:

- MS6 Chemical Feed Flowmeter

- Meter Body Connection Fittings*

- 3/16” Hex Key

- Flash Drive (Operating Manual and Blue-Central )

- USB-A to USB-C connector

- Power Supply (user configurable)

- Fittings provided with unit for installation to site piping:

- (2) ½” ID M/NPT straight fitting (PVDF)

- (2) ½” ID M/NPT 90 degree elbow fitting (PVDF)

- (2) ½” ID Hose Barb straight fitting (PVDF)

- (2) ½” ID Hose Barb 90 degree elbow fitting (PVDF)

- (2) ½”ID Slip fitting (PVC)

- TFE/P or EP O-rings. (specified when ordering unit.)

Preparation

The MS6 Chemical Feed Flowmeter is designed to withstand outdoor conditions. A cool, dry location where the unit can be easily monitored is recommended. Special ventilation is not required.

Vibration and heavy loads will damage the meter! High pressures and temperatures will damage the meter. Refer to the Pressure vs. Temperature diagram for details.

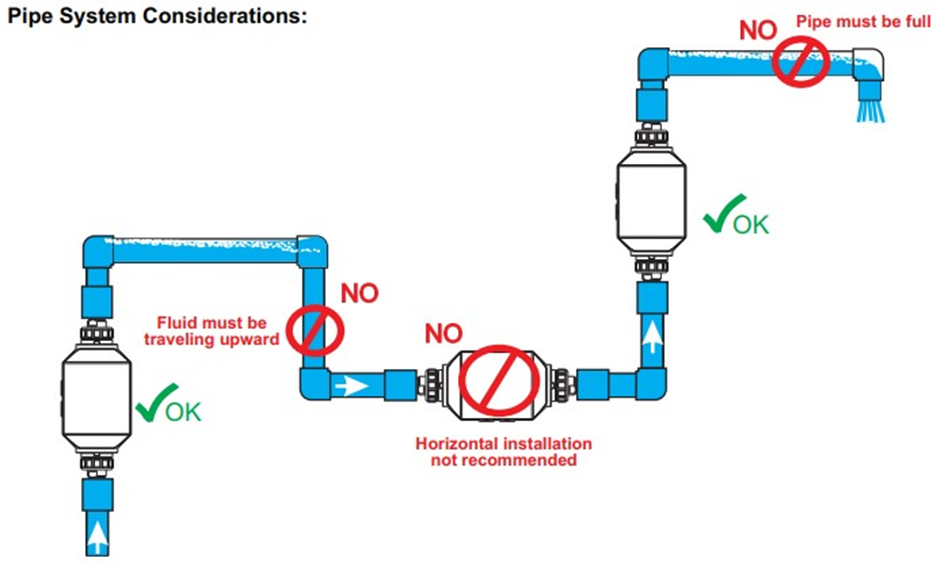

The MS6 should be located and installed in a vertical position with fluid flowing upward. This will ensure a full pipe with minimal air pockets.

If air or air bubbles are expected in the fluid, a strainer can be installed before the MS6 to reduce large particles and bubbles that can reduce signal quality. A 1/32” strainer (90008-425) can be installed at the inlet of the meter, as shown.

Piping and physical installation

The meter must be installed in a vertical plane with fluid flowing in an upward direction to ensure accuracy.

Wall, floor, and ceiling mounts and supports must be carefully aligned with the meter body and sturdy enough to support the plumbing and prevent vibration. Never allow the meter to support the weight of related piping.

The MS6 is designed with true-union style fitting connections, for ease of installation and maintenance. The MS6 can be removed without disturbing or cutting piping.

Wiring

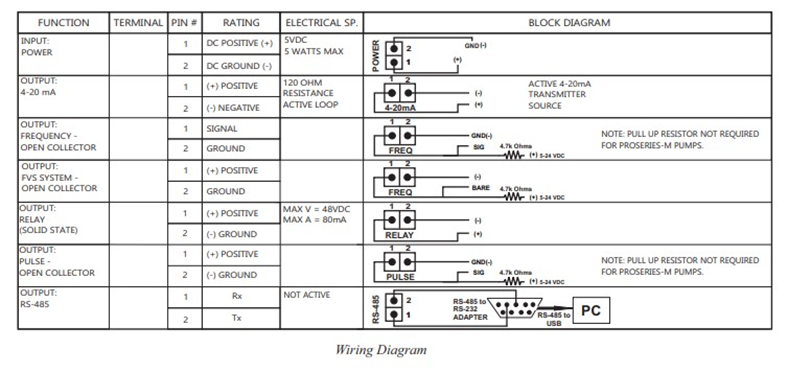

The meter must be powered by 5 volts DC. Wattage must not exceed 5 watts. DO NOT power the unit by both the transformer and USB cable at the same time. Remove power when programming the MS6 with the USB cable.

The MS6 is provided with a power supply kit, pre-wired to the unit. The power supply is configurable and will allow the user to choose an appropriate plug based on regional power.

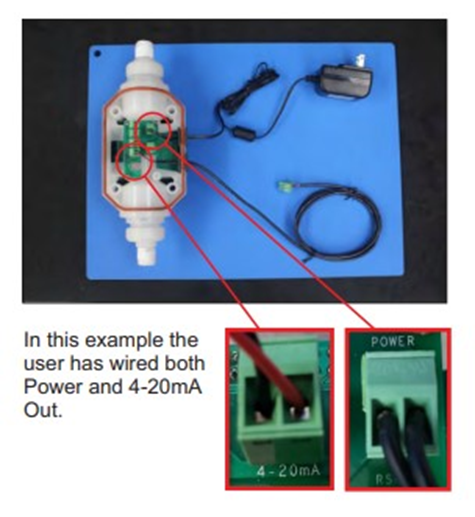

It is recommended that any signal wiring be done prior to physically installing the MS6.

20-24 AWG (American wire gauge) shielded cable is recommended for signal output connections.

The MS6 wiring compartment is equipped with two communications cable liquid-tight cable gland grommets for cable diameters from .190 to .205 inches.

Note: The blank grommet plug should be used when the communications cable grommet is not required. These are pre-installed on the unit.

To connect communications wires, the unit must be opened to access the wiring terminals. Use the provided 3/16” Hex key to remove the four Allen screws located on the rear of the unit. Be careful when removing screws and the rear panel, as the unit has interconnecting wires to the LCD screen.

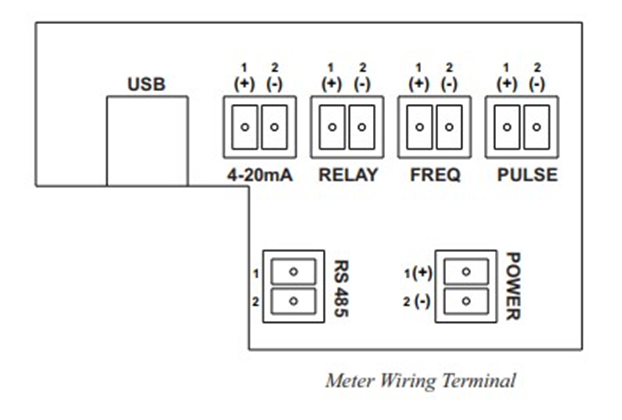

The inner wiring terminals are arranged per the below diagram.

Use shielded communication wiring and connect to terminals as shown:

Use the below Wiring Diagram for information and specifications in connecting to your electrical and control system.

Use care when reinstalling covers to maintain grommet and O-ring gasket integrity. Failure to secure covers properly may void the warranty.

Instruction for wiring Remote Display

If you have purchased the MS6 with Remote Mount Display, the unit will come pre-wired from the factory.

Refer to the instructions in the manual for detailed information.

FAQs

Frequently Asked Questions

MS6 Installation

- Can I power the MS6 meter from the pump?

The actual minimum voltage required is 3.3VDC. The maximum voltage is 9VDC. Going over 9VDC will increase heat and lower the life of the device.

Can I install the MS6 on tubing?What happens if I install the unit horizontally?How much room do I need to allow for maintenance?Can the unit be installed in direct sunlight?Should I install the unit of the suction side of the pump, or discharge?What if I need to remove the MS6 for maintenance or cleaning, but still need to feed chemicals?What Y Strainer do you recommend we use with the MS6?We recommend a standard 1/2" line Y-strainer compatible with chemical used.

What is a Y Strainer and how will it help?A Y strainer, also known as a wye strainer, is a type of filter that is used to remove solids and other particles from fluids. It is shaped like a Y, with the inlet and outlet ports located at the top and bottom of the Y, and the strainer element located in the middle. The strainer element is typically made of wire mesh or perforated metal, and it is designed to catch and trap any particles that are larger than the holes in the mesh. The strainer will keep particulates from entering the flowmeter and also help to break down large bubbles which can disrupt flow readings.

What screen size do I need to use in my Y Strainer?A 1/32" strainer is recommended to be installed before the flowmeter.

Do I have to configure the meter for it to work with Blue-Central?No, the meter comes preconfigured. The meter is pre set with a name, water profile, and an 8 second response sensitivity.

The bubble, poor signal, and empty tube warning are pre set for continue operation.

System failure fault will halt operation.

Relay output is set to totalizer with switch to open on trigger at 40mL at a 10 second trigger duration.

Frequency Output is set linearly from 0-1000Hz to correspond with 0-5000mL/min or 0-10000mL/min depending on the flow range option.

4-20mA Output is set linearly from 0-20mA to correspond with 0-5000mL/min or 0-10000mL/min depending on the flow range option.

The Pulse output is set to 50mL per pulse at 120ms pulse duration.

What fitting sizes are included with the MS6?Fittings (Included):

- PVDF 1/2” I.D. Barb

- PVDF 1/2” I.D. Barb Elbow

- PVDF 1/2” M/NPT

- PVDF 1/2” M/NPT Elbow

- PVC 1/2” Slip