What’s in the Box

The F-2000 Paddlewheel Flowmeter is shipped with the following contents:

- F-2000 Flowmeter Controller (mounted to sensor if “Sensor-Mounted” model)

- Sensor (mounted to fitting) and wiring to controller

- O-ring (for saddle mount units)

- Alignment tool (saddle mount units)

- Operating Manual(s)

Preparation

The F-2000 Flowmeter is designed to withstand outdoor conditions. A cool, dry location where the unit can be easily monitored is recommended. Special ventilation is not required.

The LCD display will degrade, and life will be reduced when installed in direct sunlight. Protect the display from direct sunlight.

Vibration and heavy loads will damage the meter! High pressures and temperatures will damage the meter. Refer to the Pressure vs. Temperature diagram for details.

Piping and physical installation

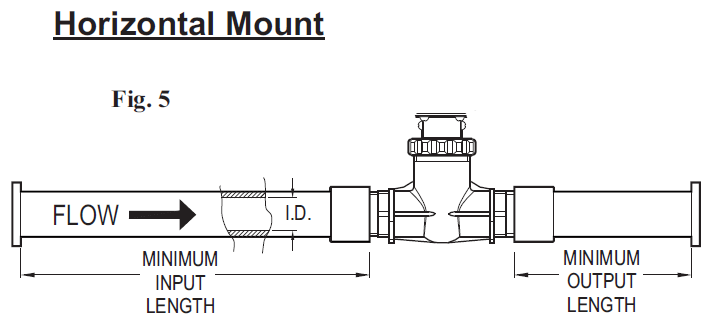

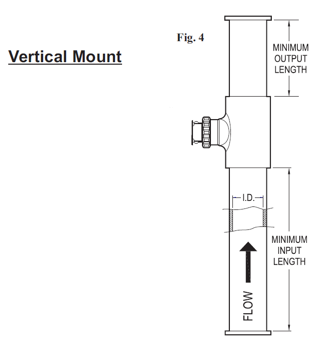

The F-2000 sensor can be mounted on horizontal or vertical runs of pipe (see figure 4, 5 and 6). Mounting anywhere around the diameter of vertical pipe is acceptable, however, the pipe must be completely full of water at all times. Back pressure is essential on downward flows.

Wall, floor, and ceiling mounts and supports must be carefully aligned with the meter body and sturdy enough to support the plumbing and prevent vibration. Never allow the meter to support the weight of related piping.

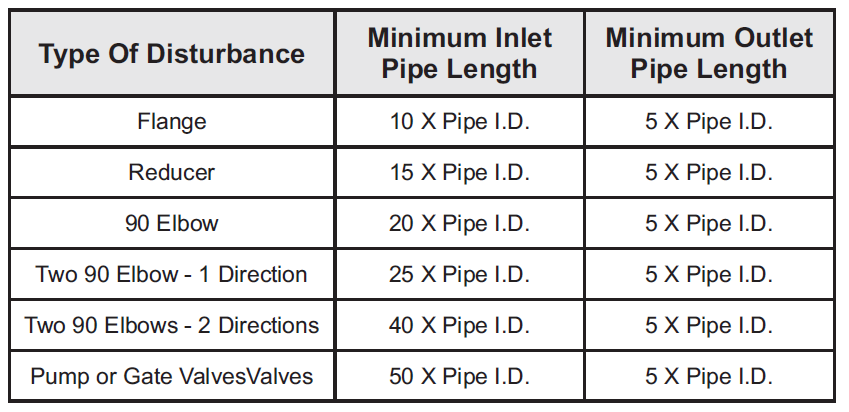

The F-2000 accuracy is affected by disturbances such as pumps, elbows, tees, valves in the flow stream. Install the meter in a straight run of pipe as far as possible from any disturbances. The distance required for accuracy will depend on the type of disturbance. At least 10X(Pipe ID) length before inlet and 5X(Pipe ID) after outlet. The straight length of pipe distance can be up 50X(Pipe ID) when downstream of control valves and pumps.

The pipe must be completely full at all times. Air bubbles or air pockets in the flow stream will adversely affect the reading. A small amount of back pressure is recommended in horizontal runs of pipe.

Pipe Flow Stream Requirements

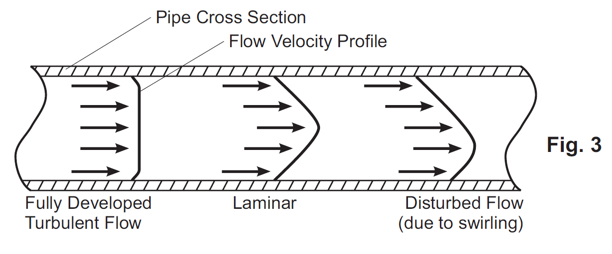

The F-2000 accuracy is based on steady, undisturbed flow with a fully developed turbulent flow profile. Pulsating, swirling and other disruptions in the flow stream will effect the meter’s accuracy.

The F-2000 is factory calibrated to ± 1% of full scale rate reading. When measuring total flow, accumulated error over time must be considered. Accuracy is based on laboratory testing of nominal pipe dimensions. Your actual accuracy will vary based on your actual pipe I.D. And other installation factors.

There are two basic types of flow profiles; turbulent and laminar (see figure 3). Turbulent flow exists when the speed of the fluid flowing in the pipe is nearly constant across the entire width of the pipe. This is typical of low viscosity fluids; like water, flowing at high velocity. Laminar flow exists when the speed of the fluid flowing in the center of the pipe is greater than the speed of the fluid at the outer edge near the pipe wall. This is typical of high viscosity fluids flowing at low velocity. Because the F-2000 is measuring the fluid near the pipe wall only (especially in larger pipe sizes), a constant flow velocity across the flow stream is required.

To determine which type of flow exists in your installation, the following is required:

Flow rate of the fluid in GPM – Q

Specific gravity of the fluid – G

Pipe inside diameter in inches – D

Fluid viscosity in centipoise – V

Use the following equation to determine the REYNOLDS NUMBER:

REYNOLDS NUMBER = (3160 x Q x G) / (D x V)

Flow conditions with a Reynolds Number greater than 4000 is fully developed turbulent flow. A Reynolds Number less than 2000 is laminar flow. The F-2000 requires a Reynolds number greater than 4000 to maintain accuracy.

Mounting Options

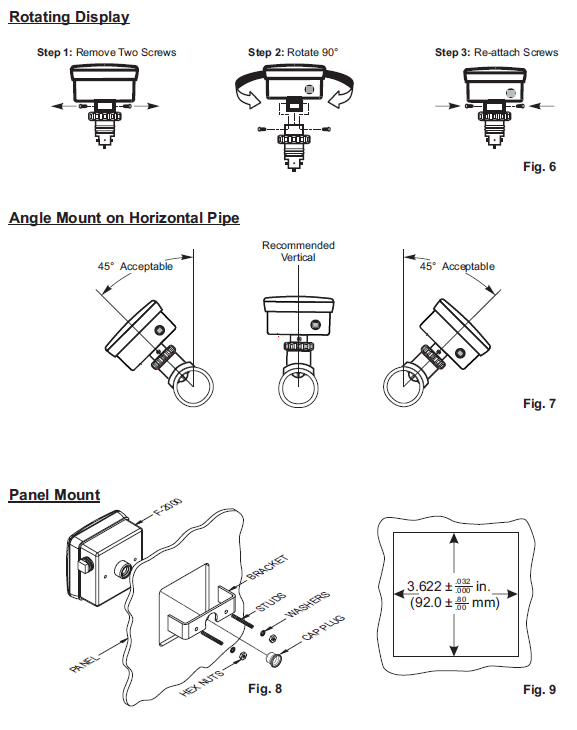

The F-2000 can be mounted to the sensor or remotely. Sensor mounting options and recommendations:

How to Install your F-2000 Saddle Fitting

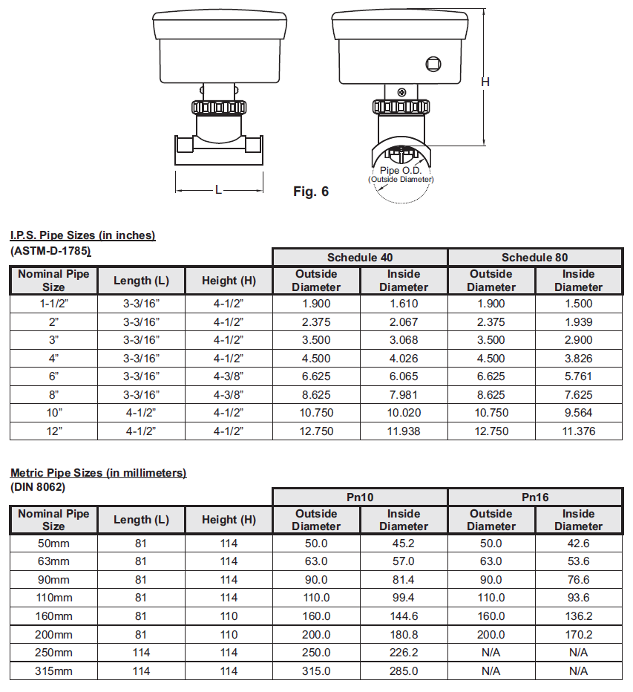

The F-2000 saddle is designed to mount on smooth schedule 40 IPS pipe, schedule 80 IPS pipe (ASTM-D-1785) , PN10 metric pipe or PN16 metric pipe (DIN 8062). The outside of the pipe must be clean, smooth, and free of surface imperfections. The outside diameter must be as specified to ensure a leak-free installation. The inside diameter must be as specified to ensure meter accuracy.

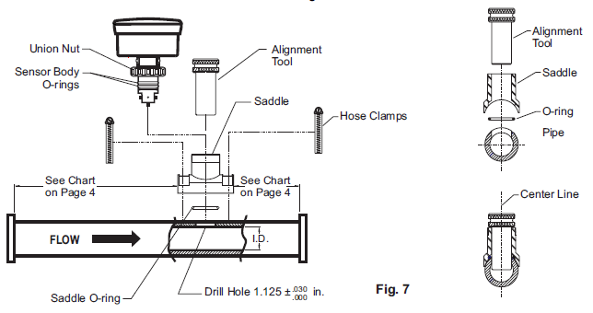

DRILL THE MOUNTING HOLE

- Select an area on the pipe as outlined in “Piping and physical installation” section. Be sure the surface area of the pipe is clean and smooth.

- Drill a 1-1/8″ diameter hole through the pipe wall. The F-2000 meter can be installed up to 45 degrees from the top of the pipe. A hole saw kit is available from the factory, order part number 20000-062.

- Clean all burrs from inside and outside the hole. Use fine sandpaper (440 grit) if necessary.

INSTALL THE SADDLE

- Insert the alignment tool through the top of the saddle. Proper alignment is critical! Slide the large O-ring over the bottom of the alignment tool and into the groove on the underside of the saddle.

- With the alignment tool and O-ring in place, position the saddle over the drilled hole. Insert the alignment tool into the hole seating the saddle. Be sure the Oring is properly seated in the O-ring groove. Place the pipe clamps around the pipe and into the slots on the saddle. Tighten the clamps in an alternating method.

CHECK THE SADDLE ALIGNMENT

- Pull the alignment tool out of the saddle. (If the tool is not easily removed, slightly loosen the clamps) Inspect the hole. The saddle must be mounted directly over the hole. Adjust the saddle alignment until the alignment tool slides freely in and out of the saddle.

- Be certain the O-ring is properly seated and visible in the groove around the hole.

- Tighten the clamps.

INSTALL THE F-2000 SENSOR

- Be sure two O-rings are located on the sensor body. The O-rings have been lubricated at the factory with silicone oil.

- Push the sensor assembly into the saddle with a twisting motion. The notch on the sensor body must fit into the slot on the saddle. Be sure the sensor is fully inserted into the saddle.

- HAND TIGHTEN the union nut.

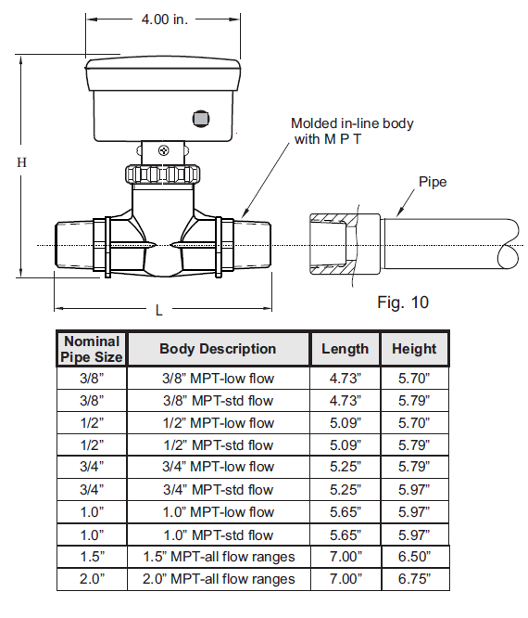

Installing the Molded In-Line Fitting (MI)

All molded in-line (MI) fittings have male American National Standard Taper Pipe

Threads (MPT).

- Select an area on the pipe as outlined in “Piping and physical installation” section. The meter can accurately measure flow in either direction provided the minimum inlet and outlet conditions are met.

- Install the F-2000 fitting as you would any other plastic pipe fitting. Be sure the inlet and outlet fittings are aligned properly. Improper alignment of the fittings will put stress on the adapter connections and may cause leaking or fitting damage. Do not over tighten the fittings. Use PTFE tape sealant only on the adapter threads.

- The F-2000 fitting can be mounted on horizontal or vertical runs of pipe. Mounting at the twelve o’clock position on horizontal pipe is recommended. Mounting anywhere around the diameter of vertical pipe is acceptable, however, the pipe must be completely full of water at all times.

- Be sure the inlet and outlet plumbing is properly secured. The F-2000 fitting is not designed to support the weight of related piping. Improperly supported pipes will put stress on the adapter connections and may cause leaking or fitting damage.

Installing the Molded PVC Tee Fitting (TE)

Select an area on the pipe as outlined in the straight length of pipe requirements.

- Remove the F-2000 sensor from the tee fitting. Do not glue the TEE while the sensor is installed.

- Install the F-2000 tee fitting as you would any other plastic pipe solvent weld (glue) fitting. Do not use too much glue. Excessive glue may create a disturbance in the flow stream, which will affect the accuracy of the meter.

- The F-2000 can be mounted on horizontal or vertical pipe runs. Mounting at the twelve o’clock position on horizontal pipe is recommended. Mounting anywhere around the diameter of vertical pipe is acceptable, however, the pipe must be completely full of water at all times.

- Install the F-2000 sensor. Be sure two O-rings are located on the sensor body. The O-rings have been lubricated at the factory with silicone oil. Push the sensor assembly into the saddle with a twisting motion. The notch on the sensor body must fit into the slot on the saddle. Be sure the sensor is fully inserted into the saddle. Hand-tighten the Union nut.

Battery Power / Wiring

The F-2000 RT Battery powered model is powered with four AA batteries. Life expectancy is one year minimum. This unit has no other wiring.

The F-2000 RT, PC, AO, and AP units require 15 VDC power. Use provided 110V/220V transformer/cable/plug, or provide 15VDC power. A Battery Back-up kit can be ordered with these units.

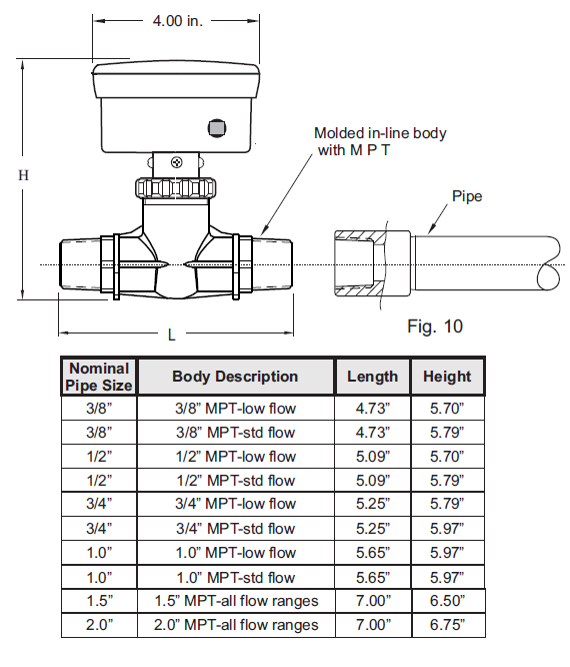

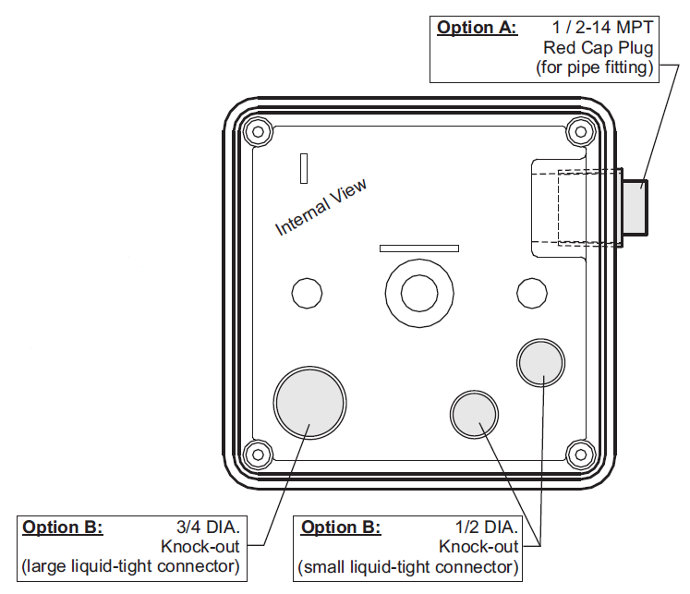

Enclosure Knock-outs

The F-2000 enclosure includes options for wiring outputs.

Option A: Qty 1 of ½ – 14 NPT male end

Option B: Qty 1 of ¾” diameter knock-out. Qty 2 of ½” diameter knock-out.

Connectors for knock-outs provided by others.

For the large liquid-tight connector (3/4” knock-out), the acceptable cable diameter is between .200 – .394 in (5.1 – 10.0 mm)

For the small liquid-tight connector (1/2” knock-out), the acceptable cable diameter is between .118 – .255 (3.0 – 6.5 mm)

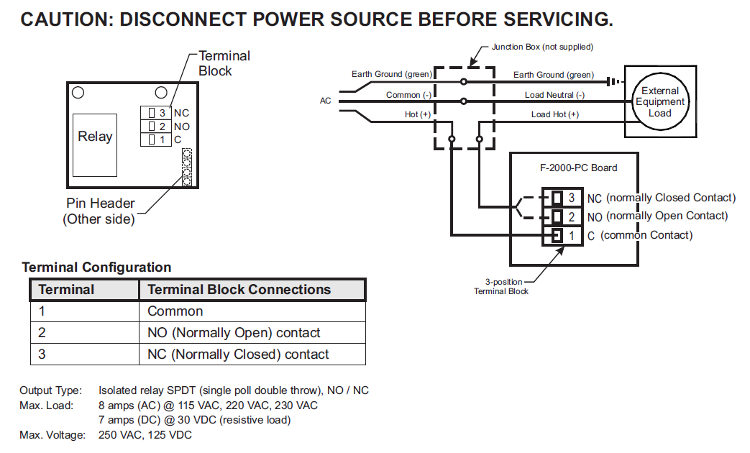

PC Model Circuit Board wiring

The F-2000 PC model includes NO/NC Relay for flow and totalization alarms.

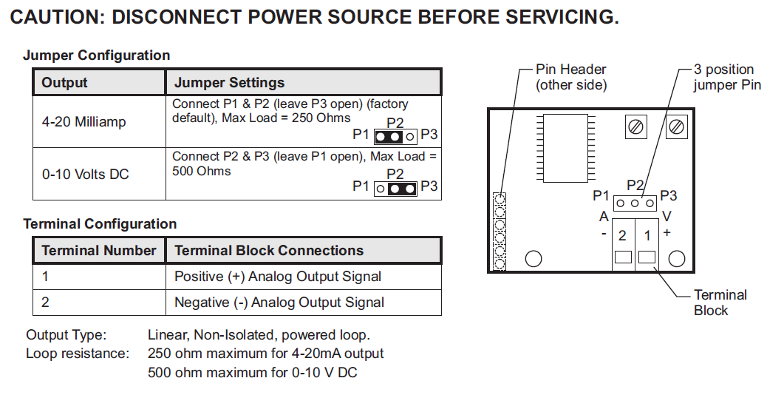

AO Model Circuit Board Wiring

The F-2000 AO Model includes an option for wiring 4-20ma or 0-10VCD outputs.

FAQs

Frequently Asked Questions

F-2000 Installation

- Can the F-2000 be installed on metric pipe?

Yes, DIN 8062, PN10 , Metric pipe sizes 50mm, 63mm, 75mm, 90mm, 110mm, 160mm, 200mm, 250mm, 315mm are available.

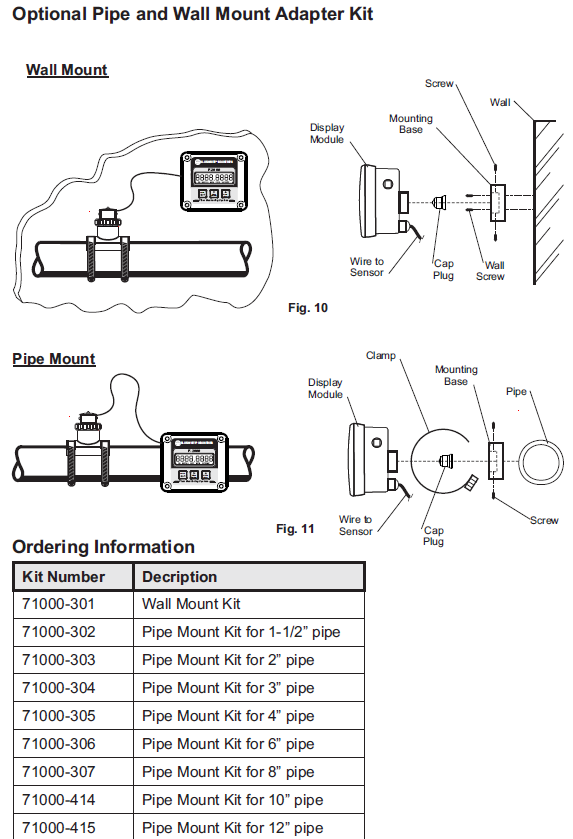

I want to remote mount the F-2000 display. Is this possible?Yes, the F-2000 display cam be remote mounted in a panel, wall or pipe mount.

What are the pipe length requirements for the F-2000?Please refer to the "Piping and physical installation" section of this page

What are the installation requirements?The F-2000 accuracy is affected by disturbances such as pumps, elbows, tees, valves in the flow stream. Install the meter in a straight run of pipe as far as possible from any disturbances. The distance required for accuracy will depend on the type of disturbance. The pipe must be completely full at all times. Air bubbles or air pockets in the flow stream will adversely affect the reading. A small amount of back pressure is recommended in horizontal runs of pipe.

Is there an option to remote mount the F-2000 display screen?Yes. The F-2000 display screen can be mounted remotely from sensor.

Can I install the meter in horizontal or vertical pipe orientation?The F-2000 meter can be installed on horizontal or vertical pipe orientation with flow directions up or down, left or right. However the minimum before and after straight lengths of pipe must be met.

I have a pipe type not listed in manual. Can F-2000 still be installed and work correctly?F-2000 is pipe size & pipe type specific. If you are installing on pipe type not listed in instruction manual, leaking may occur and meter will read and display inaccurately.