Powering On the MD3 (Legacy)

The MD3 (legacy) is powered on when plugged into the power source. The pump will take approximately 10 seconds to power on, boot, and be ready for service.

The MD3 (Legacy) pump Main Screen will appear when powered on, showing pump status, operating mode, and any alarm or errors.

Display and Layout

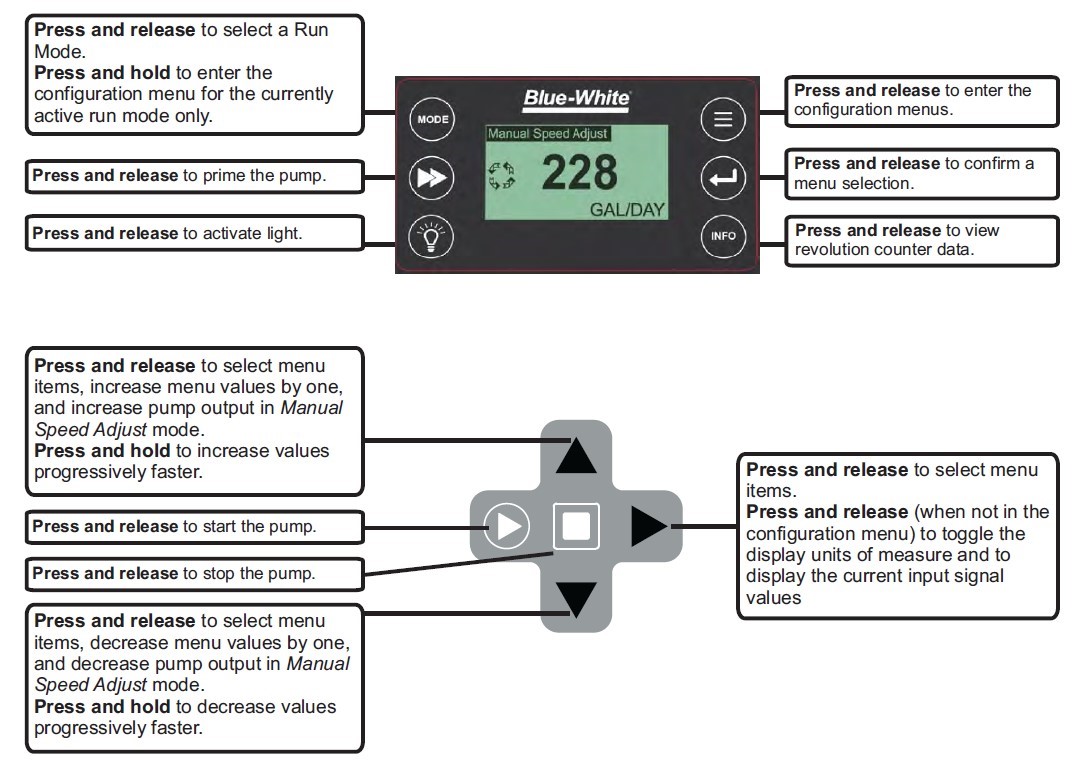

The MD3 (Legacy) has a 10-button LCD display that is easy to read and simple to use.

All pump settings can be configured by pressing the Menu button (≡), and using the other buttons to navigate. See Control Panel – Button Operation display below.

The MD3 (legacy) Pump has the following Control Buttons:

MODE – Press to scroll through run Mode. Press and Hold to configure active rune mode.

MODE – Press to scroll through run Mode. Press and Hold to configure active rune mode.  PRIME – Press to prime the pump at full speed for 60 seconds.

PRIME – Press to prime the pump at full speed for 60 seconds.  MENU – Press to access all settings and programming.

MENU – Press to access all settings and programming.  ENTER/CONFIRMATION – Used to confirm selections.

ENTER/CONFIRMATION – Used to confirm selections.  START – Press to Start pump.

START – Press to Start pump.  STOP – Press to Stop pump.

STOP – Press to Stop pump.  RIGHT ADVANCE – When in the Menu – used to select Menu items. When on main screen – used to toggle through display of flow units or incoming signal units.

RIGHT ADVANCE – When in the Menu – used to select Menu items. When on main screen – used to toggle through display of flow units or incoming signal units.  UP ARROW – When in Menu – used to toggle through menu items. When in Manual Speed Adjust mode – used to increase the speed of the pump.

UP ARROW – When in Menu – used to toggle through menu items. When in Manual Speed Adjust mode – used to increase the speed of the pump.  DOWN ARROW – When in Menu – used to toggle through menu items. When in Manual Speed Adjust mode – used to decrease the speed of the pump.

DOWN ARROW – When in Menu – used to toggle through menu items. When in Manual Speed Adjust mode – used to decrease the speed of the pump.

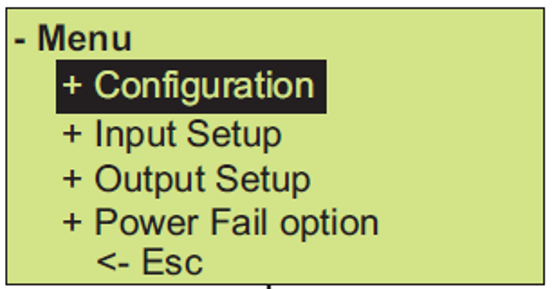

Menu Navigation for the MD3 (legacy) pump

All pump settings and programming are done via the Menu Navigation. Press the Menu button to Configure the pump and Program inputs and outputs:

Configuration

Use the Configuration to:

- Choose display language (English, Spanish, German, French)

- Set password.

- Choose display flow rate units (% speed, RPM, ml/min, Oz/min, Liter/Hr, Gal/Hr (US), Gal/day (US).

- Reset the pump to factory settings.

Input Set-up

The MD3 (Legacy) Pump includes a variety of inputs. Use the Input Setup to program the following:

- Max RPM cut-off. Allows the user to set a maximum pump speed that the pump will not exceed in any running mode, including priming the pump.

- Max Flowrate. This value is pre-set from the factory for the maximum flowrate of the MD3 pump. This setting can be used to input/change a flow value based on results from a pump calibration, as the actual flow rate will vary depending on the discharge pressure of the pump. Values entered here will directly affect the flow rates shown on the main screen during operation.

- Input Modes. Used to program settings for all operating modes.

- Contact Input. Used to program/activate input Contact Closure, used to start/stop the pump remotely. Can be disabled (default), normally open, or normally closed.

- Set FVS (Flow Verification System). – Used when pump is paired with a flow sensor. Activate by setting a delay time.

- Set DFD (Diaphragm Failure Detection). Adjust sensitivity. Default is 78%, which will detect most chemicals, but will not trigger with normal water condensation. If pumping water, we recommend setting the sensitivity to 100%. DFD is a conductivity-based sensor – a chemical solution must be conductive to be sensed.

- Remote/Local. Allows user to put the pump into “Remote Only” mode, which selects one mode to run in (no other operating modes are allowed,) or “Local Only” mode, which deactivates all remote inputs.

Operating Modes

The MD3 (Legacy) Pump includes a variety of Operating Modes. Use the Mode button to select the Operating Mode of your choice:

- Manual Speed Adjust. Choose pump speed at the pump by using up or down buttons.

- 4-20 mA. Pump will run at a speed proportional to the 4-20ma signal.

- 0 – 10 VDC. Pump will run at a speed proportional to 0 – 10 VDC signal.

- Frequency. Pump will run at a speed proportional to the Frequency signal (0-1000Hz.)

- Pulse Batch. Pump will run for a set time and speed when the pump receives a programmed number of pulse signals.

- Manual Cycle Adjust. Pump will run a repeated cycle. Set pump speed, On time, and Total Cycle time.

- Dispensing. Pump can be programmed to pump a desired total volume amount. Set the amount to be pumped and set the pump speed.

- Manual Dosing. Pump will run at a set speed based on programmed input values for % concentration of chemical, specific gravity, process flow, and PPM.

- Proportional Dosing. Pump will run at a variable speed based on programmed input values for % concentration of chemical, specific gravity, # of pulses from flow meter, and PPM.

Pump Output Setup

The MD3 (legacy) Pump includes output signals for monitoring pump status and alarms. Use the Output Setup to program the following:

- 4- 20 mA Signal Output. Used to send scaled output signal related to pump speed (flow) to a SCADA system.

- Frequency Signal Output. Used to send scaled output signal related to pump speed (flow) to a SCADA system.

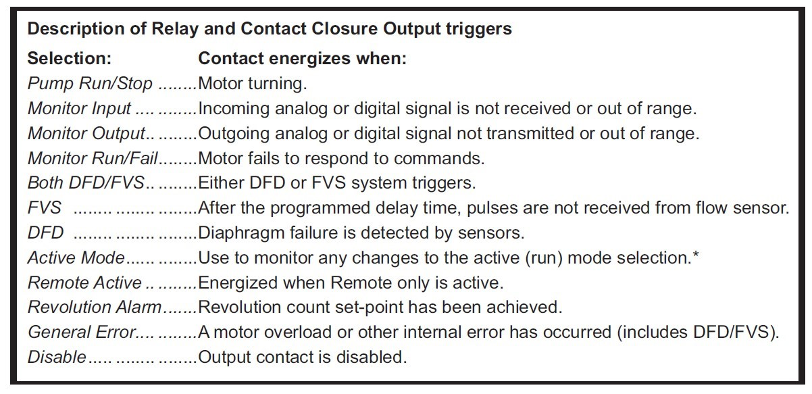

- Output Alarms. One Relay output and Three Contact Closure outputs are provided, which can be programmed for a variety of triggers (see below.)

Selection (Contact energizes when)

- Pump Run/Stop (Motor turning -roller assembly is rotating)

- Monitor Input (Incoming analog or digital signal is not received or out of range)

- Monitor Output (Outgoing analog or digital signal not transmitted or out of range )

- Monitor Run/Fail (Motor fails to respond to commands)

- 4-20 In Active (4-20mA mode is running)

- Frequency In Active (Frequency mode is running)

- Manual Speed Active (Manual Speed mode is running)

- Pulse In Active (Pulse In mode is running)

- Dispensing Active (Dispensing Mode is running)

- Manual Cycle Adjust (Manual Cycle Adjust is running)

- Remote Active (Remote Only mode is active)

- Revolution Alarm (Revolution count set-point has been achieved)

- DFD (Diaphragm failure is detected by sensors in the head)

- Both DFD/FVS (Either DFD or FVS system triggers)

- General Error (Motor Overload or other internal error)

Additional System Settings (Motor Revolution Info, Power Fail Option)

The MD3 (Legacy) Pump has a Motor Revolution Info button. This information is helpful when scheduling maintenance. The revolutions should be noted and reset whenever the pumps is serviced.

The MD3 (Legacy) Pump has a Power Fail Option that allows the user to choose whether the pump turns on in “the running state it was in when power was removed” or whether the pump powers on stopped or “OFF”.