What’s in the Box

The F-452 flow Meter is shipped with the following contents:

- F-452 Flow Meter (flowmeter may ship with plastic tube insert to prevent damage during shipping; remove plastic tube before installation)

- Quick Start Guide (QSG)

Preparation

- Remove the Flow Meter from the box. Remove the protective plastic tube. Ensure the meter, float, and guide rod are intact. Confirm flow meter is proper for your pipe size and flow.

- Identify the proper location for installation. Piping must be vertical and properly supported. The location should be in an area that allows easy reading of the meter. Misalignment of piping may damage the flowmeter and cause O-rings to leak.

Optional Shield Installation

- A Shield Kit can be purchased for use with the F-452 Flow Meter. KIT-SHL comes with a shield and two new flow meter grooved unions. To install the shield onto the flow meter, the meter must be disassembled by removing the top and bottom flow meter unions. The new flow meter unions will be used in place of the installed unions. The shield will fit into the groove of the new unions.

- Reassemble the flow meter with the shield in place. Ensure all components are installed correctly, paying attention to O-rings, guidewire, and float.

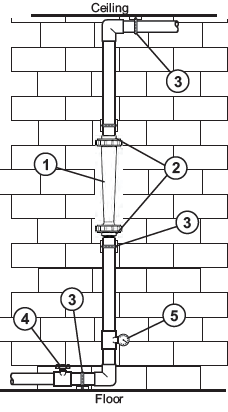

Piping and Physical Installation

1. Misalignment will damage the meter!

Flowmeter must be installed in an exact vertical plane to ensure accuracy. Be certain of proper plumbing alignments. Misalignment may cause the O-ring seals to leak. The meter body material can be damaged by UV rays. Do not install in direct sunlight.

2. Pipe dope and glue will damage the meter!

Use only PTFE tape on the threaded adapters. Polysulfone meter body and fittings cannot tolerate PVC Glue and/or pipe dope. Even fumes can cause severe damage. If you are installing your flowmeter to a glued pipe configuration, install the flowmeter after all glued fittings are dried and lines are purged of all fumes. Never hold the meter body with pliers or tools. Union nuts should be hand-tightened only. DO NOT OVER-TIGHTEN!

3. Vibration and heavy loads will damage the meter!

Wall, floor, and ceiling mounts and supports must be carefully aligned with the meter body and sturdy enough to support the plumbing and prevent vibration. Never allow the flowmeter to support the weight of related piping.

4. Solenoid valves will damage the meter!

Avoid a system that will impose a sudden burst of flow to the meter. Such a burst will cause the float to impact the float stop with destructive force. Solenoid valves or other quick-opening valves cannot be used unless the meter is protected against sudden bursts of flow.

5. High pressures and temperatures will damage the meter!

The maximum acceptable temperature and pressure is interdependent. The maximum acceptable working pressure is dependent on the actual fluid temperature. The maximum acceptable fluid temperature is dependent on the actual working pressure. (see Temperature Vs. Pressure chart).