What’s in the Box

The F-550 flow Meter is shipped with the following contents:

- F-550 Flow Meter (flowmeter may ship with plastic tube insert to prevent damage during shipping, remove plastic tube before installation)

- Quick Start Guide (QSG)

Preparation

- Remove the Flow Meter from the box. Ensure the meter, float, and guide rod are intact. Confirm flow meter is proper for your pipe size and flow.

- Identify the proper location for installation. The flow meter must be vertical and properly mounted/supported. The location should be in an area that allows easy reading of the meter.

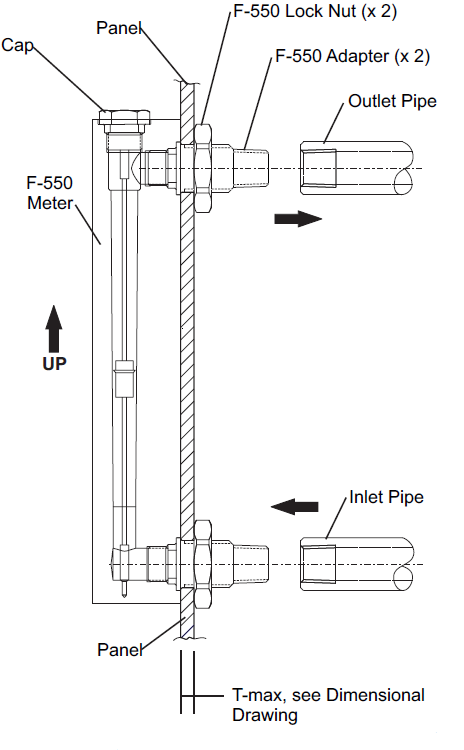

Piping and Physical Installation

STEP 1. Unpack the flow meter

- Check for damage while unpacking the flow meter.

- Be sure the meter is suitable for your application.

- Check maximum temperature and pressure.

- Although the meter may be suitable for other chemicals, Blue-White meters are tested with water only. If you are unsure of the meter’s compatibility with your chemical, consult the factory.

- Blue-White guarantees the meter is suitable with water only.

STEP 2. Choose a suitable location for the flow meter

- Never allow the flow meter to support the weight of related pipe or tubing.

- Flow meter must be installed in plumbing which is free of vibration.

- Flow meter must be installed in an exact vertical plane to ensure accuracy.

- Valves – Avoid a system that will impose a sudden burst of flow (water hammer) to the meter. Such a burst will cause the float to impact the float stop with destructive force. Magnetic, solenoid, ball, or other quick-opening valves cannot be used unless the meter is protected against sudden bursts of flow.

- Do not exceed maximum working pressure (see Temperature vs. Pressure chart).

STEP 3. Connecting the flow meter to the plumbing

- Use an appropriate amount of PTFE (or similar) tape on external pipe threads before making connections.

- Acrylic and other exotic plastics cannot tolerate PVC Glue and/or pipe dope. Even fumes can cause crazing. If you are installing your flow meter to a glued pipe configuration, install flowmeter after all glued fittings are dried and lines are purged of all fumes.

- Install the meter to the panel using the panel lock nuts. Do not over-tighten.

- The meter adapters are provided with wrench flats. Prevent the meter adapters from rotating while attaching the inlet and outlet plumbing. Be careful not to damage the plastic threads.

- Maximum panel thickness:

1/2” (13 mm) for F-55250, F-55375, F-55376, F-55500

13/16” (21 mm) for F-55750, F-55010, F-55015, F-55200