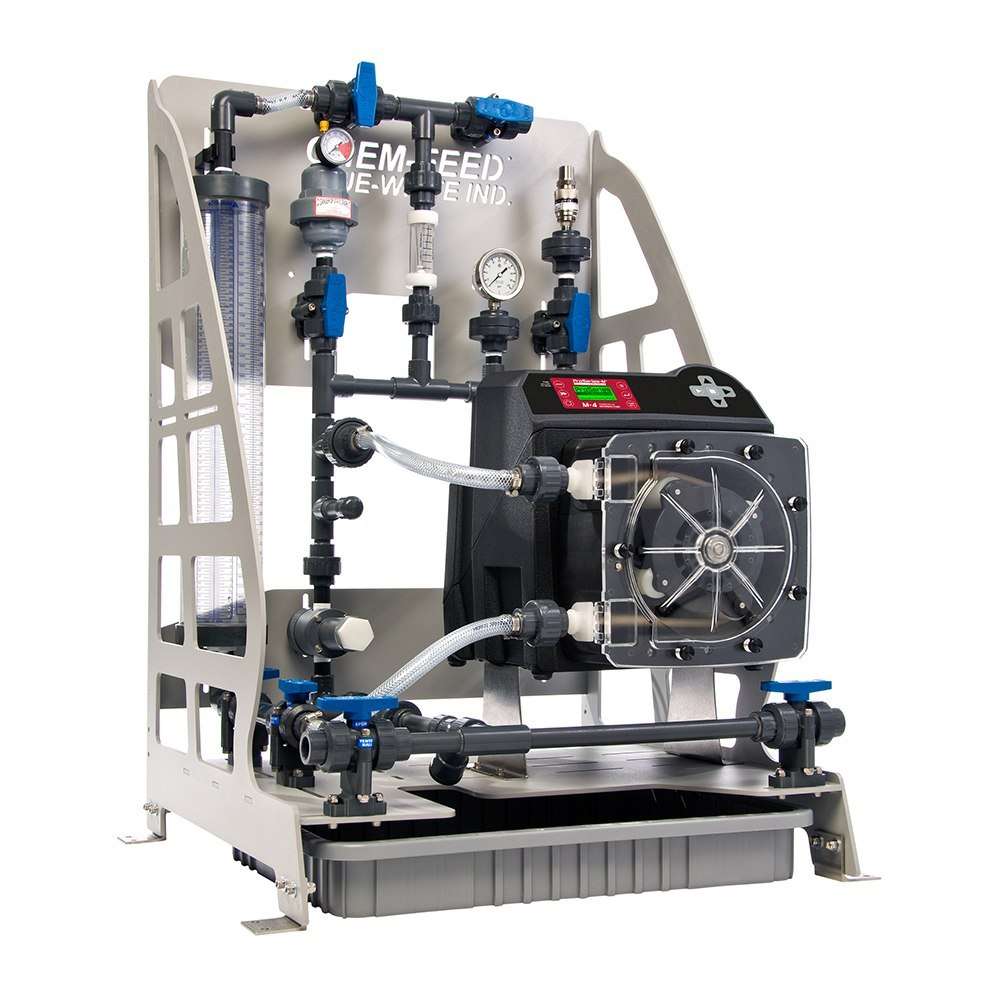

CFS-1-M

CHEM-FEED® Aluminum Simplex Skid System

The prefabricated design of the CFS-1-M Aluminum Simplex Skid System (For municipal applications) allows for easy installation; simply drop the Skid System in place and make your connections.

Technical Overview:

System Type

Single pump system

Product Compatibility

M1, M2, M3, M4, MD1, MD3, MC2, MC3

Frame Material

Powder coated aluminum

Mounting Position

Floor or Wall

PSI

150

Bar

8.6

Literature

CFS-1 Literature

Instruction Manuals

CFS-1 | CFS-2 Municipal Instruction Manual – 80000-596Technical Data Sheets

CFS-1 Municipal Technical Data Sheet – 85000-172Catalog

Municipal Catalog 2023Features

CHEM-FEED® Engineered Skid Systems were designed and engineered using solid modeling tools for superior piping installation and easy component maintenance. Custom engineered universal mounting blocks and pre-machined mounting slots provide for easy component servicing and replacement. Lightweight for wall or floor mounting.

Benefits:

- Efficient, Small footprint Design

- The prefabricated design allows for easy installation, simply drop the skid system in place and make your connections

- Each system is rigorously factory tested

- Includes pressure switch option

- Easy access to wiring components from the rear of the system

- Joints use Weld-On 724 solvent cement which is chemically resistant to Sodium Hypochlorite and other chemicals

- Dual side inlets enable connection of multiple skids to the same inlet

- Available with the factory options, Custom modifications are not possible

What’s Included:

Standard

- Corrosion Resistant – CHEM-FEED® skid system frame constructed of chemically resistant polyester powder coated 6061 T6 aluminum. Welded joint construction

- Mounting Pads – Stainless Steel mounting pads to secure CHEM-FEED® System to a solid surface. Designed for floor mount or wall mount

- Pressure Relief Valve x1 – Protects the system from over-pressurization, 5-100 psi setting range, 150 psi maximum system

- pressure.

- Check Valve x1 – Protects the user from back-flow during pump maintenance.

- Flow Verification Sensor – MS6 accurately verifies liquid chemical feed. Exclusive to Blue-White®

- Inlet Y Strainer x1 – Recommended for Diaphragm Pump systems.

Optional components (see product matrix)

- Calibration Cylinder – Confirm pump output under system conditions. Specify cylinder volumes from 1.6 GPH to 32 GPH

- Pulsation Dampener – Protect the system components from pulsation. Recommended for diaphragm pump systems only

- Pressure Gauge with Guard – Isolate and protect the system pressure gauge. Specify pressure ranges from 0-100 psi, or 0-200 psi

Specifications

Skid Frame

- Chemically resistant polyester powder coated 6061 T6 aluminum. Welded joint construction.

Pump (sold separately)

- FLEXFLO® model M2, M3 or M4 peristaltic pumps or CHEM-FEED® model MD3, MC2 or MC3 diaphragm pumps

Piping

- PVC Schedule 80 (optional CPVC).

Tubing (T)

- Reinforced braided PVC, 200 Psi max, meets NSF std. 51. The pump inlet and outlet flexible tubing connections are terminated to half unions and secured to the barbed fitting with stainless steel clamps. The calibration cylinder fill

Tubing clamps

- 300 series SS band, 400 series SS screw

Unions (U)

- PVC body, schedule 80, FKM seals

Ball valves (V)

- Vented type ball, True unions, PVC body, PTFE shaft bearings and seats, FKM seals

Pressure Relief Valve (PRV)

- PVC body, PTFE primary diaphragm seal. Non-wetted components: FKM secondary seal, zinc plated steel spring, stainless steel external hardware, HDPE pressure adjusting screw and locknut. Infinite adjustment from 5- 100 psi. Maximum inlet pressure 150 psi.

Calibration Cylinder (CC)

- PVC body, PVC end caps, 1/4” ID tubing outlet vent.

- Available volumes: 1.6 GPH (100ml), 4 GPH (250ml), 8 GPH (500ml), 16 GPH (1000ml), 32 GPH (2000ml).

Pulsation Dampener (PD)

- CPVC body,10 cubic inch volume, FKM bladder (optional EPDM bladder)

Gauge w/guard (G)

- Gauge: liquid filled stainless steel with blowout plug, bottom mount, 1/4” NPT threads.

- Available pressure ranges: 0-30 psi, 0-100, psi, 0-200 psi.

- Guard: PVC body, FKM diaphragm seal, temperature compensated oil filled.

Check Valve (CV)

- PVC body, FKM diaphragm (optional EPDM). Cracking pressure: 1.0-1.5 psi.

- Maximum working pressure: inlet = 150 psi, back = 100 psi.

Flow Indicator (F)

- Machined cast acrylic, PVC connections, ceramic ball, polypropylene ball stop, PVC half unions, FKM seals (optional EPDM).

Y Strainer (S)

- PVC body, FKM seals (optional EPDM).

MS6 Chemical Flowmeter (FVS)

- PVDF & PEEK body, PVC socket weld connections, FKM seals (optional EPDM). Available working flow ranges:

- 10-5,000 ml/min (0.158 – 79.2 GPH

- 100-10,000 ml/min (1.58 – 158.0 GPH)

Universal mounting blocks

- PVC

Pump extended mounting brackets

- 316 Stainless Steel

Skid mounting foot / wall pads

- 316 Stainless Steel

Mounting hardware

- 18-8 Stainless Steel

Drip Tray

- Polypropylene,16” x 21” x 3” – 4 gallons total containment

Maximum working pressure

- 125 psig (8.6 bar)

Operating Temperature

- 14 F to 115 F (-10 C to 46 C)

Approximate Shipping Weight (pump ships separately)

- Single Pump System: 60 lb. (27.2 Kg)

- Dual Pump System: 70 lb. (31.8 Kg)

Videos

Nothing to display here

Accessories

Downloads

| Title | Size | Update Date | Download |

|---|---|---|---|

|

CFS-1 | CFS-2 Municipal Instruction Manual – 80000-596 |

6.33 MB | April 15, 2024 | Download |

|

CFS-1 Municipal Technical Data Sheet – 85000-172 |

694.09 KB | July 18, 2024 | Download |

|

CHEM-FEED® Skid Systems Quick Start Guide – 80000-470 |

1.60 MB | June 14, 2024 | Download |

|

Municipal Catalog 2024 – 80000-708 |

13.09 MB | July 16, 2024 | Download |