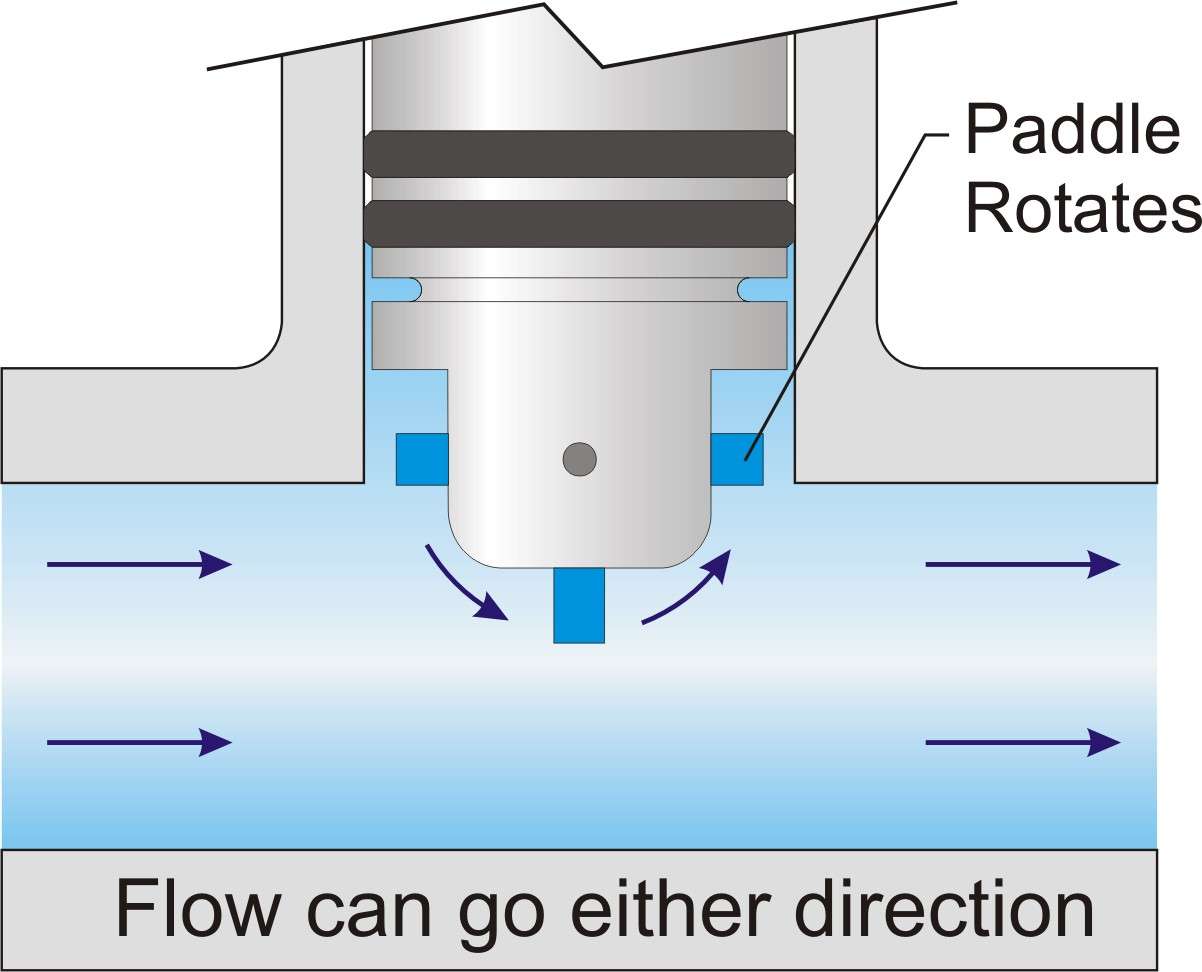

WHAT IS A PADDLEWHEEL FLOW METER?

A device used to measure the flow rate of a fluid in a system. It incorporates a rotating paddlewheel that spins as the fluid passes through.

MANAGING COSTS USING PADDLEWHEEL FLOW METERS

Digital Paddlewheel Flow Meter

Relatively low-cost paddlewheel-style electronic flow meters are proof that high cost doesn’t always mean better value.

Electronic flow meters used to control metering pumps and other industrial water treatment system components, can be very costly. While many of these meters are extremely accurate and offer a variety of features, these features are often underutilized and overqualified for the application.

The components of a system must be able to perform the required task – get the job done – and meet the other physical requirements of the application. Excess capability, features, and accuracy are a waste of money. You will get the most value for your money by purchasing system components that meet the demands of the system without being overkill. While expensive, high technology solutions may be available for your application; low-cost paddlewheel flow meters offer high accuracy solutions (to +/- 1% of the full-scale reading) for many industrial water treatment applications.

Paddlewheel flow meters are easy to install and operate, resulting in a very low overall cost of ownership.

INDUSTRIAL WATER TREATMENT SYSTEM APPLICATIONS

Paddlewheel flow meters can control inexpensive metering pumps.

Chemical metering pumps are used to inject chemicals such as chlorine and acids into water systems, and the chemical must be injected into the system at the proper rate to achieve the correct water/chemical proportions. In a system that has varying water flow rates, solenoid-driven metering pumps are often used. These pumps can be “pulsed” by an external controller or PLC resulting in intermittent small injections of chemical per volume of water flow.

Paddlewheel flow meters can be used to start and stop inexpensive, motor-driven fixed feed rate metering pumps without the need for expensive PLCs or other control equipment. When the meter has determined that a preprogrammed volume of flow has passed through the system, control circuitry in the meter turns on the chemical pump for a pre-programmed amount of time, usually a few seconds, and then back off again. Although this method results in an uneven “pulsed” dispersion of chemical in the system, it is simple to install and results in a highly accurate, easy-to-maintain proportional feed system.

In some applications, uneven chemical injection results in portions of the flow stream that have not been treated with chemical, especially at very low injection rates. If a finer dispersion of chemical is required, variable speed peristaltic (squeeze tube) metering pumps can be used. The new generations of high-pressure peristaltic metering pumps are equipped with variable speed motors resulting in the continuous injection of chemical instead of interrupted “pulsed” chemical injection. These pumps have the ability to pump air eliminating vapor lock and lost prime issues, and they can prime against maximum back pressure. The output remains the same regardless of changes in system pressure. The peristaltic pump’s speed can be controlled directly by a paddlewheel sensor’s high-speed frequency signal. The pump speed is programmed to react to changes in the frequency output by the flow sensor resulting in highly accurate proportional feed even at very low injection rates.

FLOW VERIFICATION

Paddlewheel flow meters can verify that chemical injection has occurred.

Paddlewheel sensors are capable of measuring chemical metering pump output rates as low as One ounce per minute. When installed on the metering pump, the flow sensor can be used to alert the system operator that an error exists in the system. Some metering pumps include electronics that react to the paddlewheel output signal. If the metering pump should fail to inject chemical due to a pump malfunction, clogged fitting, exhausted chemical container, etc., an alarm output is triggered.

FLOW RATE AND RANGE ALARMS

Paddlewheel flow meters can monitor a system’s flow rate.

When a system’s flow rate is critical, a paddlewheel flow meter can be used to alert the system operator if the rate increases or decreases out of a programmed range. The electronic display can be programmed with high and low rate parameters which will trigger an alarm output signal if reached. The alarm can automatically reset or latch. Trigger and release values can be set, with hysteresis, which will eliminate “flickering” that can occur when the flow rate is at the alarm value.

INSTALLATION REQUIREMENTS

- Paddlewheel flow meters work best with clean fluids. Particles and debris can prevent the paddle from spinning properly.

- Install the pipe fitting in a location that includes a proper length of straight pipe before and after the meter. Because the paddle is inserted only a small distance into the flow stream, the flow stream must be a consistent velocity across the entire inside pipe diameter to obtain an accurate reading. The straight length of the pipe will allow any swirl patterns in the flow stream to dissipate before contacting the paddlewheel. Swirl patterns can be caused by obstructions such as an elbow, tee, pump, etc. The minimum straight length of pipe required will depend on the type of obstruction before the paddlewheel. The absolute minimum is typically ten times the nominal pipe size before the meter and 5 times after. Thus, a 4″ pipe would require a minimum of 40″ (10 x 4) of straight pipe before the paddlewheel and 20″ (5 x 4) after. Refer to the manufacturer’s instructions for specific requirements.

- Paddlewheel flow meters may not function properly with high viscosity fluids. High viscosity fluids will tend to produce a laminar-type flow profile. In a laminar flow profile, the center of the flowing fluid is moving faster than the outer edge. A turbulent flow profile, where the fluid velocity is the same across the entire pipe diameter, is required for accuracy. The fluid’s Reynolds Number must be greater than 4000 to ensure a fully developed turbulent flow profile. The Reynolds Number is a dimensionless number that combines the effects of viscosity, density, and flow velocity to identify either a turbulent or laminar flow profile.

- The pipe must be full of water at all times. When the system starts and stops, any air in the line may lead to an erroneous reading.

- Size the meter to work towards the low end of the published operating range. Operating at the high end of the range will result in greater wear on the sensor components. Although the meter may read at flow rates other than published, the meter may not be accurate at these rates.

- Be sure the saddle is properly installed. Saddle installation, pipe size, alignment, and adjustment, are critical to an accurate reading.

Written by:

Blue-White® Industries

714-893-8529