Flow Meters and flow measurement has been around for thousands of years as farming, irrigation, and water conservation became an integral part of civilization. Rudimentary flow meters were evident as far back as the early Roman Era.

The flow meter was enhanced in the 17th century when the mathematical foundations of flow theory evolved and today the variety of available flow meters styles has grown enormously from those early beginnings.

Some examples of flow meters types include: variable area, positive displacement, ultrasonic, and mass flow meters. Each type of flow meter has unique features that will fit with the corresponding application and industry. How do you choose which flow meter is right for you?

The variable area flow meter is the most cost-effective solution for almost all applications. The variable area flow meter is a meter that measures fluid flow by allowing the cross-sectional area of the device to vary in response to the flow, causing a measurable effect on the rate. The variable area flow meter offers many advantages over some more technologically advanced types, contributing to its popularity for use in many flow measurement applications.

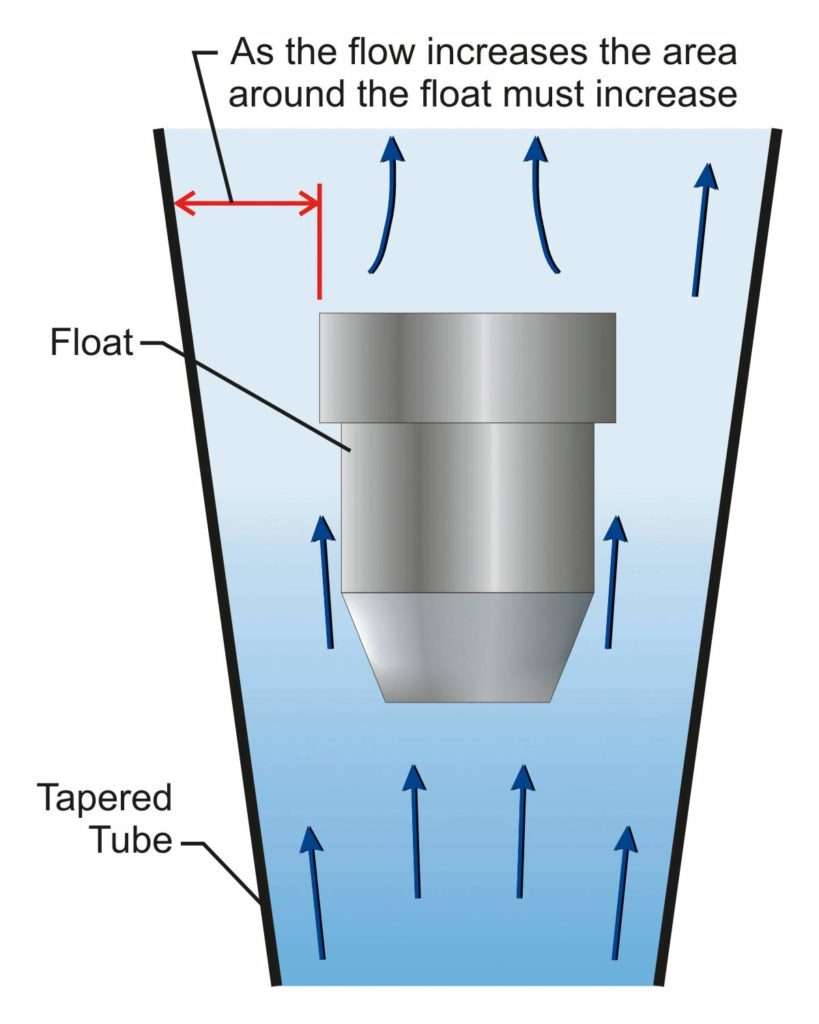

TAPERED TUBE

The flow meter body is a vertically tapered tube. The fluid passes from the smaller end to the larger end of the taper. As the fluid flows through the tube, it forces an indicator (float) upward. The clearance space (annular area between the float and the tube wall) between the float and the tube increases as the float moves towards the top of the meter. The larger clearance area towards the top requires a larger amount of fluid to force the float higher. The greater the flow, the higher the float is raised. By varying the taper of the tube, as well as the mass of the float, and the length of the tube, different flow ranges can be calibrated.

A scale with flow increments or measurements is typically printed next to the tube or on to the tube itself. The flow rate can be read by matching the increments on the calibrated scale with the edge of the float.

Proper installation of a variable area flow meter is critical to performance. The meter must be plumbed into the piping system with the narrow part of the taper at the bottom (inlet).

COMPETITIVE

Variable area flow meters have become very competitively priced making them far more cost effective in recent years. As more manufacturers enter the market, prices remain steady or in some cases are down. Compared to more advanced technology variable area flow meters are a real bargain.

A few of the industries where the use of variable area flow meters is common to include the following: The food and beverage industry, agriculture, irrigation, carwash, and industrial and municipal water treatment industries all use variable area flowmeters. These industries require the installer and user to monitor flow accurately and economically, thus enabling critical process adjustments to be made.

Variable Area Flow meters which are manufactured so that there is no metal in the fluid path are an excellent option in applications where the manufacturing and management of deionized water is done. Ultrapure water is used extensively in the manufacturing of printed circuitry.

COMPATIBILITY

The variable flow meter user must be certain to check chemical compatibility. Don’t rely solely on compatibility charts. The user should perform their own testing. Many flow meter manufacturers, including Blue-White, are willing to provide material sample kits so that the user can perform a compatibility test.

Specific gravity (weight) of the liquid through the flow meter affects flow meter reliability and accuracy. Viscosity, the degree to which fluid resists flow under applied force, and elevated temperatures also affect accuracy. Most flow meters are manufactured and tested using water so adjustments must be made when measuring other fluids.

ACCURACY AND REPEATABILITY

Accuracy and repeatability will determine the correct flow meter to purchase for each application. It is important to determine what various terminologies mean. For example, a flow meter that claims 2% accuracy does not tell the whole story. This could mean 2% of the full scale or 2% of the indicated flow, which are very different measures of accuracy and could confusion. Be certain to check with the manufacturer regarding accuracy claims.

Repeatability is the flow meters’ ability to reproduce flow rates consistently under the same conditions. Repeatability is crucial in the processing industry where tracking flow changes is so essential.

It is best to have a clear understanding of your flow measurement requirements before you purchase a flow meter. Consult an expert if there are any questions about which is the best flow meter for an application.

Blue-White has technical engineers who can provide friendly assistance and accurate information to assist customers in choosing the best variable area flow meter for their application.

Written By:

Jeanne Hendrickson, Blue-White Industries