Drinking water and wastewater treatment systems play a crucial role in ensuring healthy communities and healthy ecosystems. One fundamental parameter that significantly influences the efficiency and performance of these treatment systems is the pH level of the water being treated. The pH level affects both the chemical and physical properties of the water, thereby influencing the behavior of contaminants and treatment processes.

Operators must have a thorough understanding of how pH impacts treatment processes in order to ensure those systems perform as needed, and to avoid potential harm to equipment, people, and the environment.

Understanding pH

The pH of water is a measure of its acidity or alkalinity and is defined on a logarithmic scale ranging from 0 to 14. A pH of 7 is considered neutral. Values below 7 indicate acidity, and values above 7 indicate alkalinity. Fluctuations in pH are normal, but generally should be limited to between 6.3 and 7.6. As pH shifts above or below desired levels, operators may need to add chemicals to bring levels back within the acceptable range.

Acidic water can be adjusted by adding soda ash (sodium carbonate) or sodium hydroxide via a chemical metering pump (Figure 1).

Conversely, alkaline water can be controlled through the addition of liquid acids or carbon dioxide (CO2).

Maintaining pH is most important in the following stages of the treatment process:

Coagulation and Flocculation

For larger water treatment plants, coagulation and flocculation are key treatment stages. Maintaining the pH within a specific range (generally between 6 and 8) helps optimize the performance of the coagulant and enhances the formation of larger, more settleable flocs. Deviations from the optimal pH range can lead to incomplete flocculation, poor sedimentation, and reduced efficiency of subsequent filtration processes.

Disinfection

Disinfection is a crucial step in water treatment that eliminates harmful microorganisms to ensure the safety of the water supply. Chlorine-based disinfectants work most efficiently at pH values between 5.5 and 7.6. The pH level needs to be carefully monitored and adjusted to ensure adequate disinfection and prevent the formation of disinfection byproducts, such as trihalomethanes (THMs), which are more likely to form at higher pH levels.

Collection and Distribution

The pH of water also plays a crucial role in maintaining the integrity of wastewater collection systems and drinking water distribution systems. For this reason, many industries are required to treat their wastewater before discharge, including pH adjustment. When the water is too acidic or too alkaline, it can cause metals to leach into the water. Then again, scaling occurs when the water has a high pH and contains elevated levels of hard minerals, leading to the deposition on pipes and fixtures.

Biological Processes

In wastewater treatment systems, biological processes such as activated sludge treatment or biological filtration are used to remove organic matter and nutrients. The pH level influences the activity and growth of microorganisms involved in these processes. Different microorganisms thrive in different pH ranges, and maintaining the appropriate pH conditions is crucial for the stability and effectiveness of biological treatment systems.

How To Measure and Adjust pH

Operators can measure pH using any inline probe or, for more complete analysis and data collection, a Water Analyzer (Figure 2), which is designed to measure pH levels.

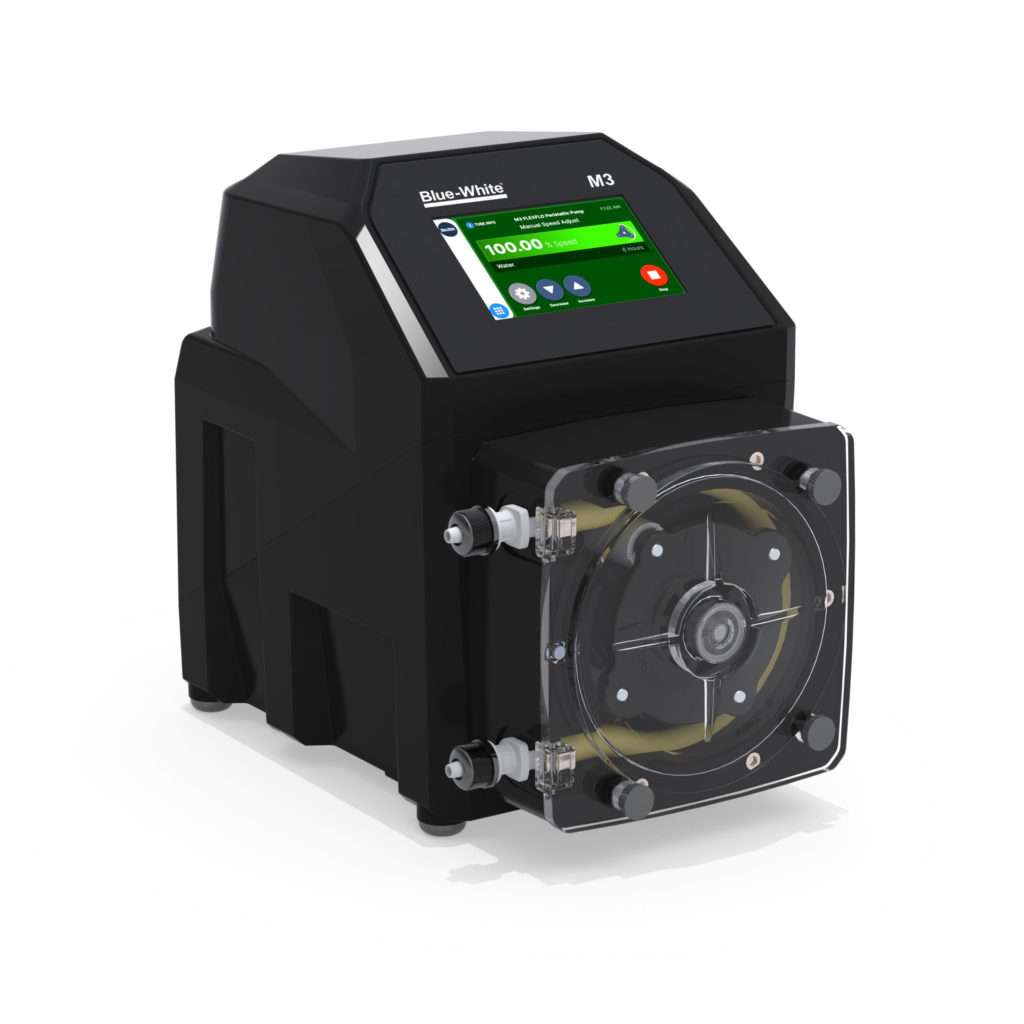

When pH levels need to be adjusted, many facilities choose chem treatment using Chemical Metering/ Dosing Pumps. System designers and operators must be careful to choose the correct pump for the chemical being dosed. This includes choosing the proper pump component materials, including valves and pump tubes/ hoses. They must be compatible with caustic and abrasive acids and bases.

FLEXFLO® M3 Chemical Metering Pumps dependably deliver smooth, accurate chemical dosing and operators appreciate the pump’s bright, easy access and highly responsive 5-inch display screen. This intuitive screen is as simple to operate as a smart phone and features easily recognizable icons. FLEXFLO M3 pumps have a broad 10,000:1 turndown ratio to meet a vast range of dosing requirements, and they’re equipped with a brushless DC motor for trouble-free and energy-efficient service. M3 remote control signal options include Pulse, 4-20mA, Modbus TCP, EtherNet IP, and PROFIBUS for enhanced supervision and automation for critical metering and transfer applications.

Lastly, operators need to carefully consider the type of acid or base used for pH adjustment. For example, sulfuric acid can quickly and dramatically lower pH, but it also produces high levels of heat when mixed with water, which can be problematic and even dangerous in some applications.

CO2 dosing (Figure 3) provides a more controlled and gradual pH reduction. CO2 is self-buffering, forming carbonic acid (H2CO3) when dissolved in water. This carbonic acid can dissociate into hydrogen ions (H+) and bicarbonate ions (HCO3-). The reversible equilibrium reaction between carbonic acid and bicarbonate ions helps maintain the pH of the solution, typically keeping it just above 6. Thus, it is difficult to over-dose the water. This reduces the risk of corrosion, minimizing the risk of water quality deterioration due to the release of metals or other pipe-related contaminants.

CO2 may not be an ideal solution for treating highly alkaline water. However, for the majority of water systems it does represent an advantage and is recognized as environmentally friendly.

No matter which method of treatment is used, the fact remains that pH level plays a significant role in every stage of water and wastewater treatment. By recognizing the impact of pH and implementing appropriate control strategies, operators can ensure consistent treatment outcomes.

Written by:

Blue-White® Industries

714-893-8529