Industrial Skid Systems

Skid systems can be complicated – designing and selecting components for a successful chemical feed system can be difficult, expensive, and require long lead times.

Explore our industrial skid systems below

Explore Industrial Skid Systems

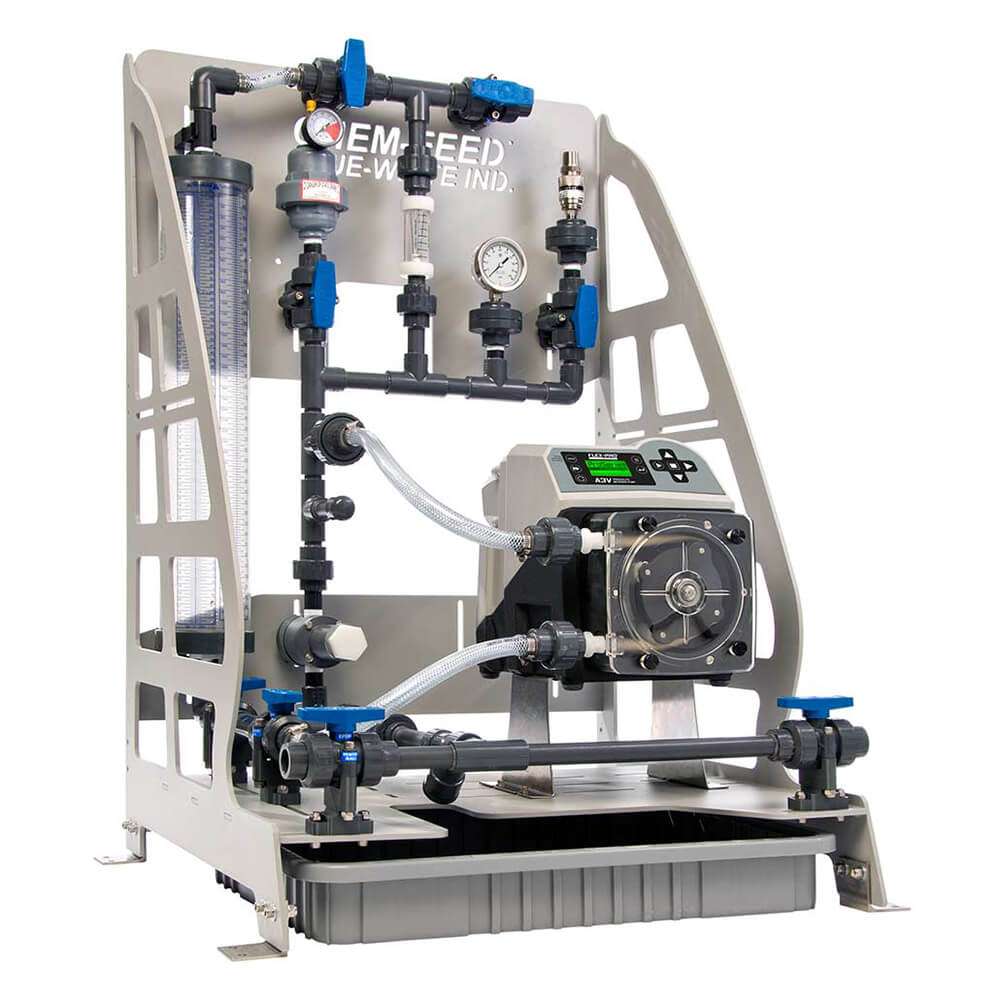

CFWS-1

CHEM-FEED® Wall Mount Simplex Skid System

| System Type | |

|---|---|

| Single pump system | |

| Frame Material | |

| Polyethylene | |

| PSI | Bar |

| 150 | 10.3 |

CFWS-2

CHEM-FEED® Wall Mount Duplex Skid System

| System Type | |

|---|---|

| Duplex pump system | |

| Frame Material | |

| Polyethylene | |

| PSI | Bar |

| 150 | 10.3 |

CFPS-1

CHEM-FEED® Plastic Simplex Skid System

| System Type | |

|---|---|

| Single pump system | |

| Frame Material | |

| Polyethylene | |

| PSI | Bar |

| 150 | 10.3 |

CFPS-2

CHEM-FEED® Plastic Duplex Skid System

| System Type | |

|---|---|

| Duplex pump system | |

| Frame Material | |

| Polyethylene | |

| PSI | Bar |

| 150 | 10.3 |

CFPS-3

CHEM-FEED® Plastic Triplex Skid System

| System Type | |

|---|---|

| Triplex pump system | |

| Frame Material | |

| Polyethylene | |

| PSI | Bar |

| 150 | 10.3 |

CFS-1

CHEM-FEED® Aluminum Simplex Skid System

| System Type | |

|---|---|

| Single pump system | |

| Frame Material | |

| Powder coated aluminum | |

| PSI | Bar |

| 125 | 8.6 |

CFS-2

CHEM-FEED® Aluminum Duplex Skid System

| System Type | |

|---|---|

| Duplex pump system | |

| Frame Material | |

| Powder coated aluminum | |

| PSI | Bar |

| 125 | 8.6 |

CHEM-FEED® Skid System Upgrades

Blue-White offers four different pipe materials on our skids to ensure maximum chemical compatibility. In addition, we provide an optional pressure switch and back pressure valve. Customizable options are also available.

Advantages of a Skid System

-

Streamlined start-up

Ships fully assembled for easy installation, saves time during start-ups

-

Cost effective

Less expensive than having a contractor run piping and instruments

-

Simplifies maintenance

Much better site maintenance compared to pumps mounted on barrels

-

Saves floorspace

Saves space on plant floor especially when wall mounted

We are here to help you

For assistance, please call our offices at +1 (714) 893-8529 or reach out to us by clicking below. We look forward to serving you.